Smartbond Litz Wire

General

Products for multimedia applications are increasingly equipped with wireless charging devices. ELEKTRISOLA's Smartbond OSP18 has been developed to meet the needs of these specific charging systems. This self-bonding litz wire combines excellent bond strength with good windability, fast soldering, and very good hot air bonding characteristics.

The hot air bonding process is environmentally friendly compared to solvent bonding process, allows faster winding, and has potential for process automation. Very thin coils can be produced with Smartbond`s unique construction giving additional space for designers or to help to achieve miniaturization goals.

Features and benefits of Smartbond litz wires

- excellent bonding strengths with hot air bonding

- high winding speed

- solderable without pre-stripping of insulation

- environmentally friendly automated process due to elimination of solvents

- thin walled overcoat allows small coils

- customized wall thickness possible per customer specification

Technical properties of Smartbond litz wire

| Standard Litz Wire | Served Litz Wire | Selfbonding Litz Wire | Smartbond | |

|---|---|---|---|---|

| Stability of coil | - | good | medium | good |

| Flexibility / windability | soft | more stiff | soft | soft |

| Bonding process | - | solvent | hot air | hot air |

| Mechanical protection | avg | good | avg | good |

| Surface and haptic | - | rough | avg | smooth |

| Second adhesion step without additional adhesion |

no | no | limited | yes |

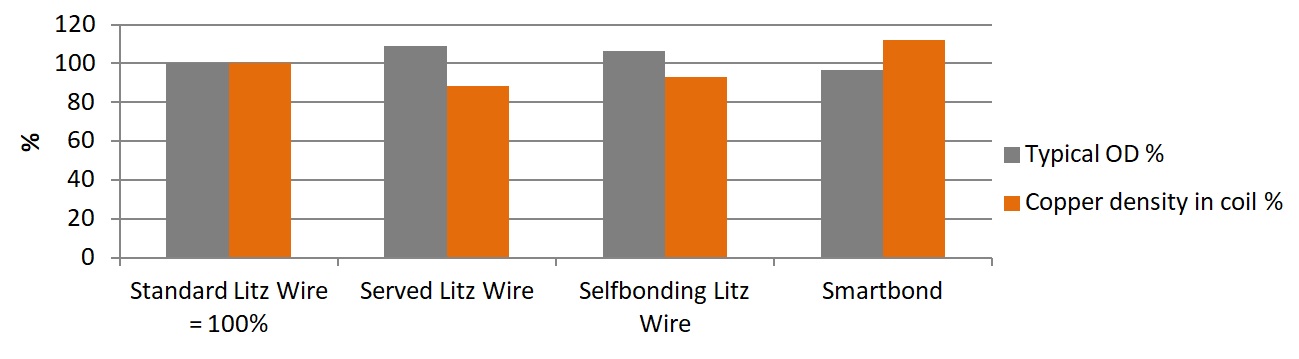

Diameter of litz wire and copper fill factor

Dimensions

| Diameter of single wires | 0.020 - 0.500 | mm |

| Outer diameter of litz wires | 0.500 - 3.500 | mm |

Applications

- transmitter coil for wireless charging

- receiver coil for wireless charging

- wireless power charger

- coreless coils in different applications