Taped Litz Wires

Taped high frequency litz wire constructions are mainly suitable for applications requiring high break down voltage. Taping improves the capability to withstand flexing and mechanical stress. Adhesive taped litz wire can be achieved by using thermally sealed or self adhesive tape. This ensures protection against re-opening during and after manufacturing processes and thus secures the compliance with defined creepage distance.

Some tapes can be thermally sealed when used in conjunction with certain wire enamel types.

Excellent adhesion and bonding characteristics to the individual wires are possible. A wide range of thermally sealable tapes can be selected for special applications all promoting various degrees of flexibility and mechanical protection for the litz wire construction.

Features and benefits of taped litz wires

| Variants | Dielectric strength | Flexibility | Splicing | Contacting |

|---|---|---|---|---|

| Standard | high | very good | good | very good |

| Thermally Sealed | elevated | medium | very good | very good |

| Self-Adhesive | very high | good | very good | good |

| Taping materials | PET | PEN | PI | |

|---|---|---|---|---|

| Description | Polyester | Polyethylene Naphtalate | Polyimide | |

| Color | transparent | transparent | brown | |

| Standard | PET | PEN | PI | |

| Insulation class (UL) | °C | 105 (A) | 180 (H) | 200 (C) |

| Insulation class (VDE) | °C | 130 (B) | - | 200 (C) |

| Dielectric constant | ℇr | 3.3 (VDE 0345) |

2.8 (JIS C 2318) |

3.4 (ASTM D 150-92) |

| Flammability | 400 (VDE 0345) |

VT-M (UL 94) |

V-0 (IEC 60695-11-10, UL 94) |

|

| UL-file no., tapes | E53895 | E206562 | E39505 | |

| Processing | fusible | fusible | mechanical stripping | |

| Thermally Sealed | ||||

| Insulation class (UL) | °C | 13 - 25 | - | 20 |

| Insulation class (VDE) | °C | 9 | - | 0.2 - 0.5 |

| Dielectric constant | ℇr | 3.25 (ASTM D 150-81) |

- | 3.4 (ASTM D 150-92) |

| Flammability | n.a. | - | V-0 (IEC 60695-11-10, UL 94) |

|

| UL-file no., tapes | E93687 | - | E39505 | |

| Processing | fusible | fusible | mechanical stripping | |

| Self Adhesive | ||||

| Insulation class (UL) | °C | 130 (B) | 180 (H) | 180 (H) |

| Dielectric constant | ℇr | 3.2 (JIS C 2318) |

2.8 (JIS C 2318) |

3.3 (JIS C 2318) |

| Flammability | - | flame retardant (internal test acc. UL 510) |

flame retardant (internal test acc. UL 510) |

|

| UL-file no., tapes | E515235 | E515235 | E515235 | |

| Processing | fusible | fusible | mechanical stripping |

Custom materials can be arranged

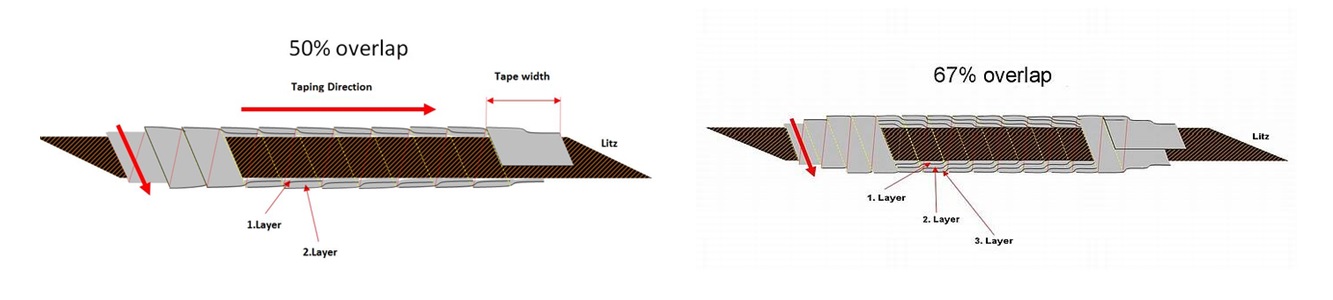

Degree of overlapping

The degree of overlapping of two adjacent tape windings is defined by the gradient angle between tape and litz wire during the taping process. The overlapping determines the number of tape layers located on top of each other and thus the thickness of the insulation.

Dimensions

| Diameter of single wires | 0.040 - 0.700 | mm |

| Outer diameter of litz wire | 0.5 - 20.0 | mm |

| Overlapping (typical) | 50 or 67 | % |

| Number of tapes (typical) | 1 - 2 |

Applications

- EV (Electric Vehicles)

- OBC (Onboard charger)

- DC/DC converter

- Wireless charging

- Charging piles

- SMPS (Switch Mode Power Supplies)

- HF transformers

- HF transducers

- HF chokes