利兹线

历史

20世纪上半叶,利兹线的应用范围和当时的技术水平相一致。例如,1923年,第一次中频无线电广播因采用了利兹线线圈而得以实现;1940年代,利兹线被使用于第一台超声诊断系统和射频识别系统;1950年代,利兹线被使用于超短波扼流圈。20世纪下半叶,伴随着新型电子元器件的爆炸式增长,利兹线的应用也因而迅速扩大

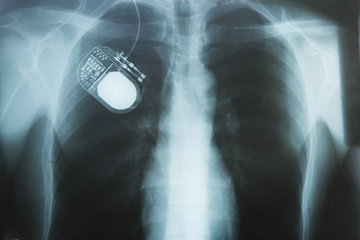

1951年,益利素勒开始供应高频利兹线,以满足客户对创新质量产品需求的不断增长。益利素勒的利兹线被迅速应用于新型的设计中,如1960年代电磁镇流器中的铁氧体磁心扼流圈,1970年代和1980年代的磁共振成像系统,1990年代的高频开关电源。

从一开始,益利素勒就在与客户共同开发创新型利兹线方案中扮演着积极的合作伙伴的角色。这种对客户的紧密支持延续至今,新的利兹线应用正在可再生能源、电动交通和医疗技术领域被开发并应用于未来的新产品中。

定义

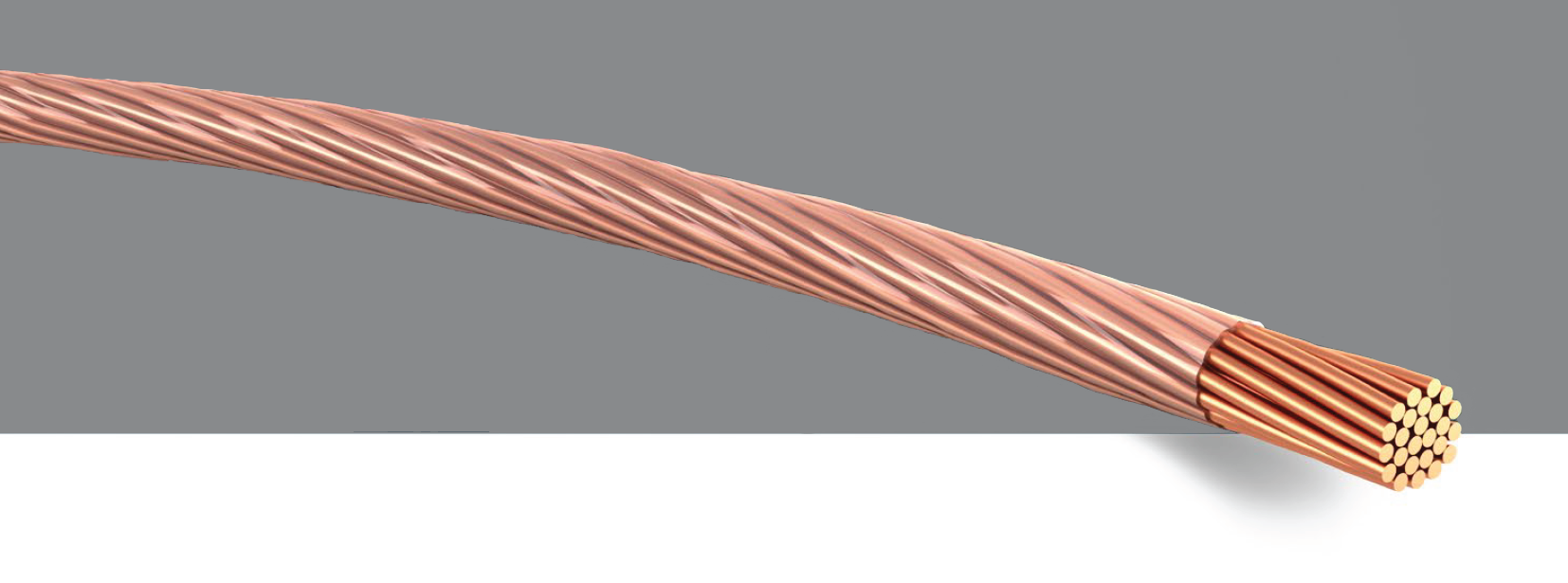

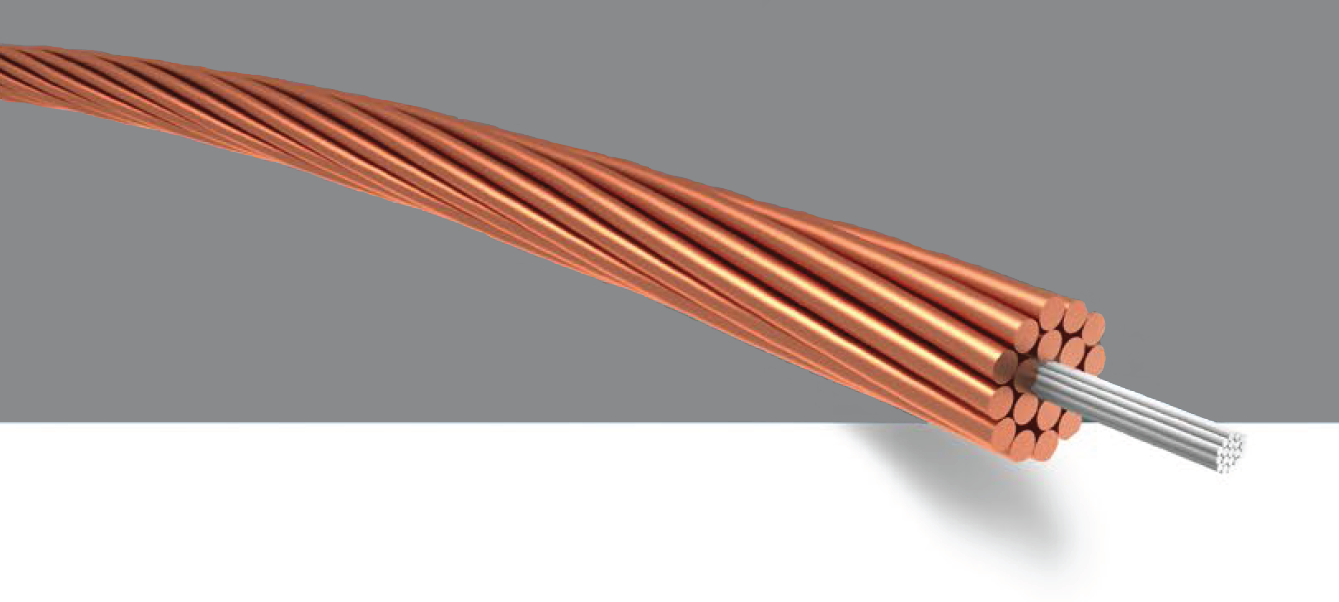

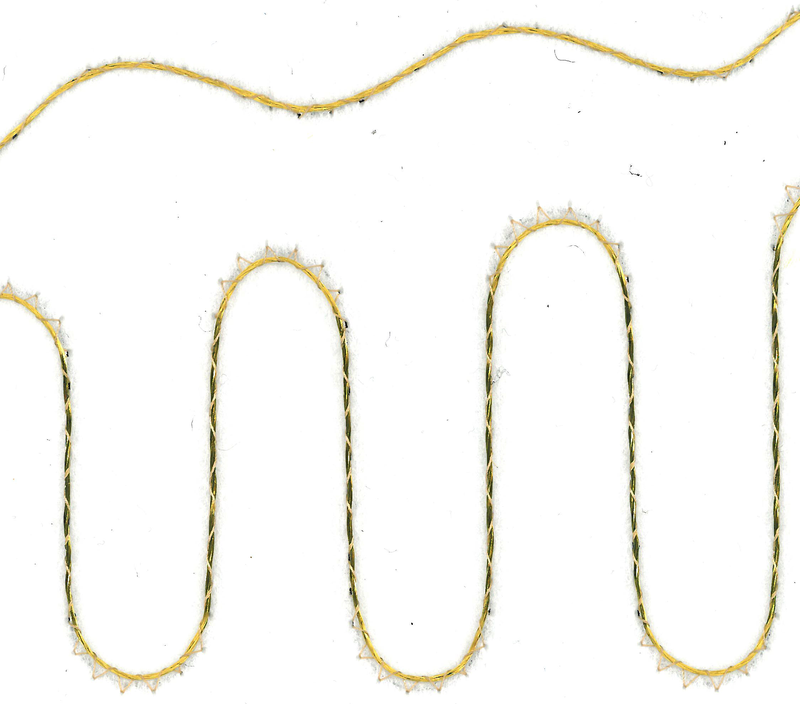

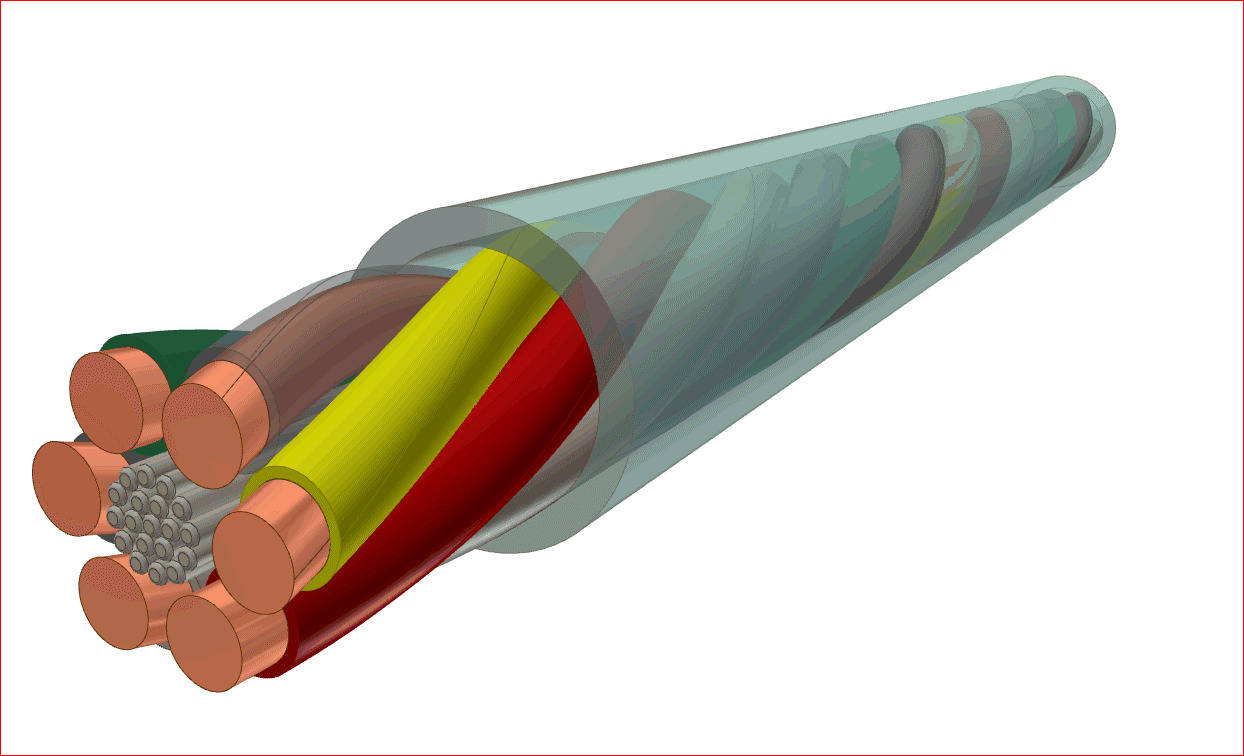

利兹线由多根单股绝缘线组成,被广泛应用于需要良好柔韧性和高频性能的场合。

高频利兹线是使用多股相互绝缘的单线绞合而成,通常用于工作频率在10 kHz 至 5 MHz之间的应用。

在磁储能线圈的应用中,高频会产生涡流损耗。涡流损耗随着电流频率的增加而增加。这些损失的根源是趋肤效应和邻近效应,它可以通过使用高频利兹线来减少。这些由磁场引起的损耗可以通过利兹线的绞合结构进行克服。

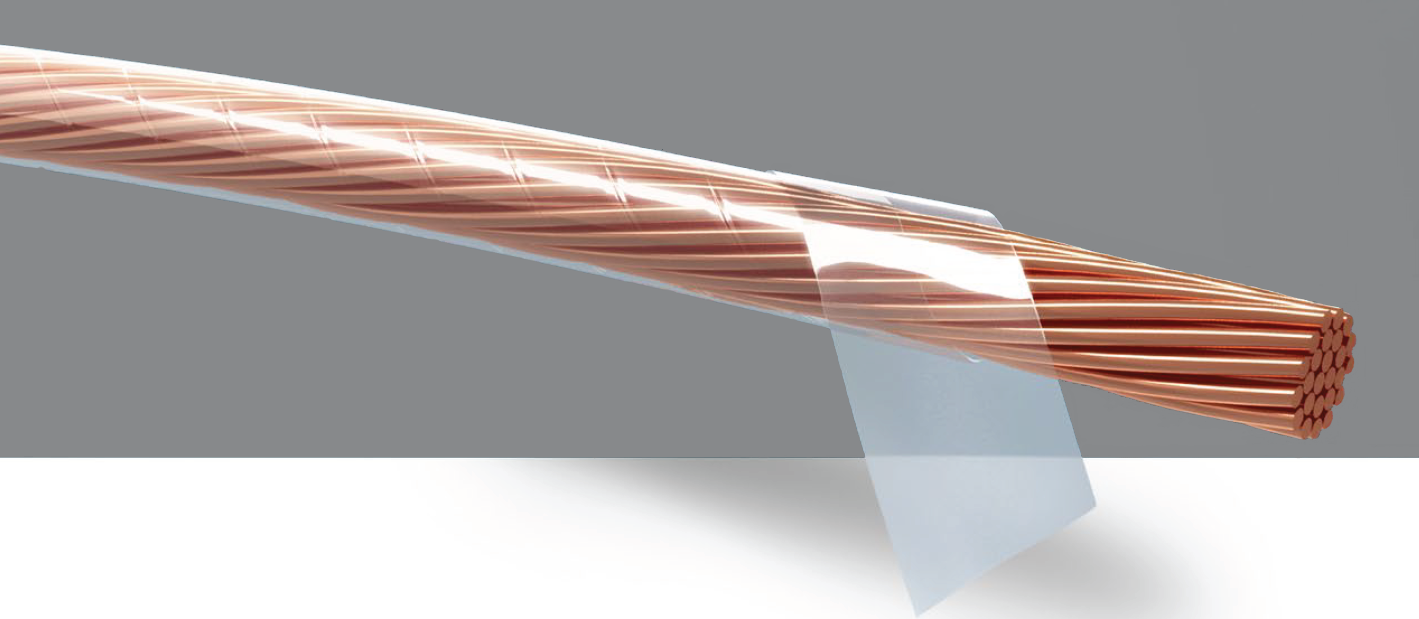

单股线

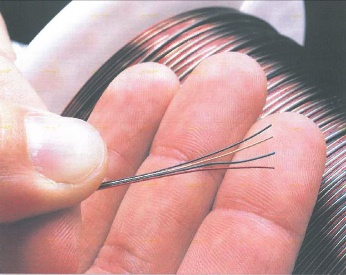

利兹线的基本组成单位是单股漆包线。为满足不同的应用要求,导体材料和绝缘漆可以选取各种优化的组合。

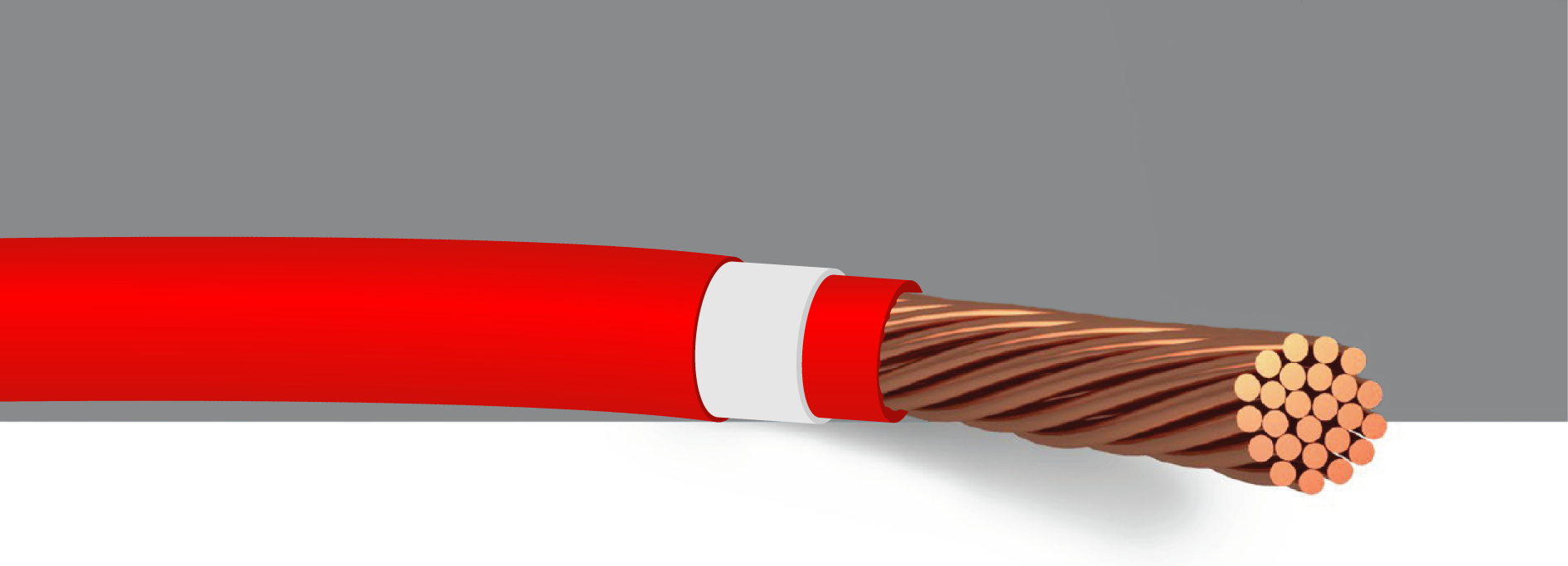

利兹线 / 线束结构

根据单股线的数量,利兹线需要一个或多个生产步骤。因此,对于整体设计有很多选择。

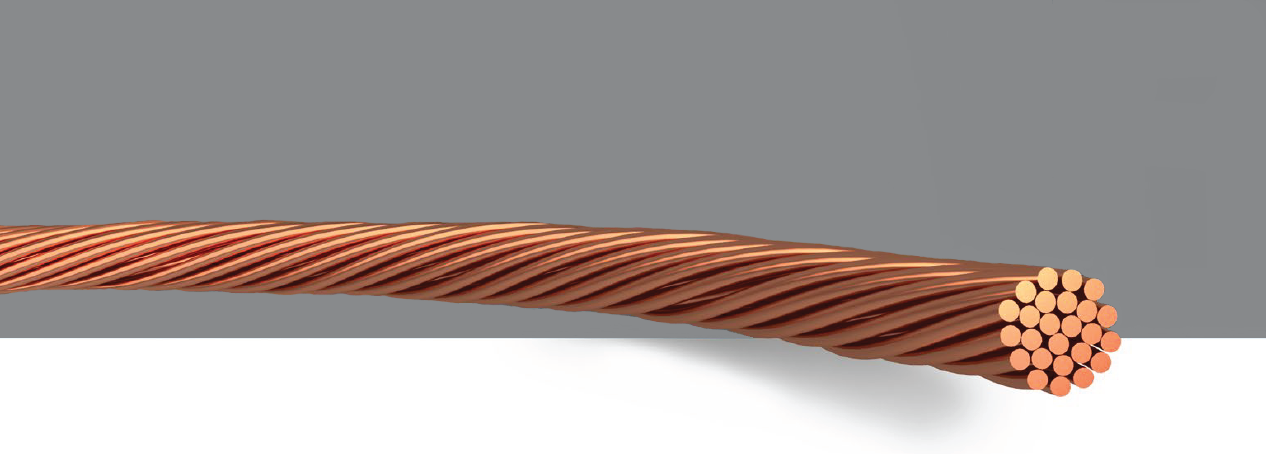

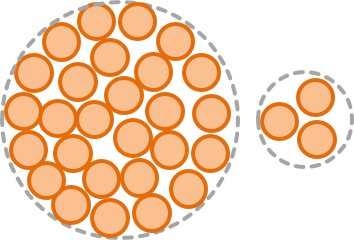

直接绞合利兹线

有限数量的单股线被直接绞合,每股单线被自由排列,在利兹线的截面上单股线可能处于任意位置。

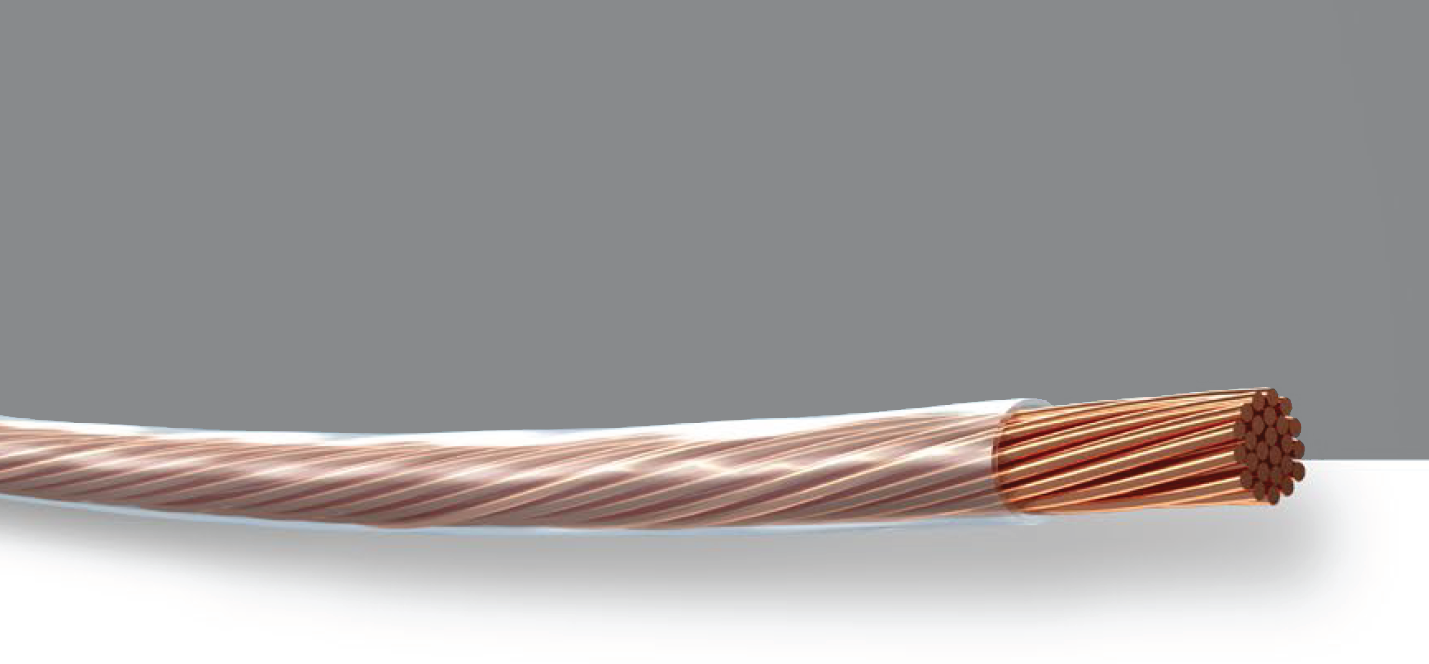

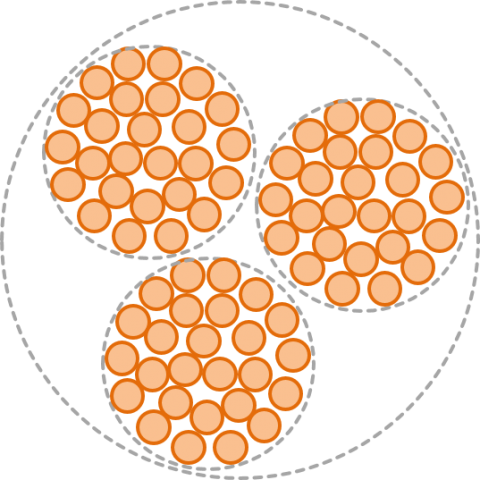

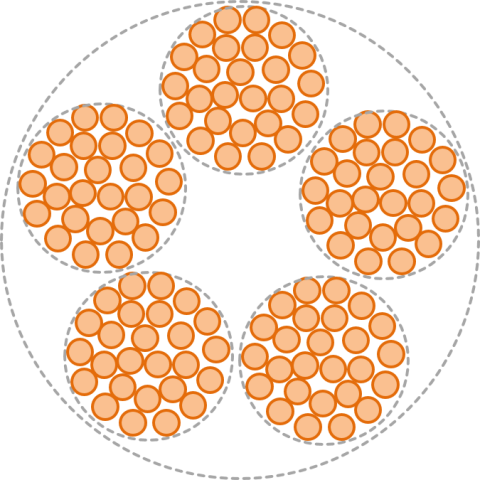

复绞利兹线

根据特定的形状,利兹线可以进行多个步骤扭绞,预先扭绞好的多股线可以按照要求的数目继续进行多次绞合。成品的电气性能和机械性能取决于所设计的利兹线绞合结构。

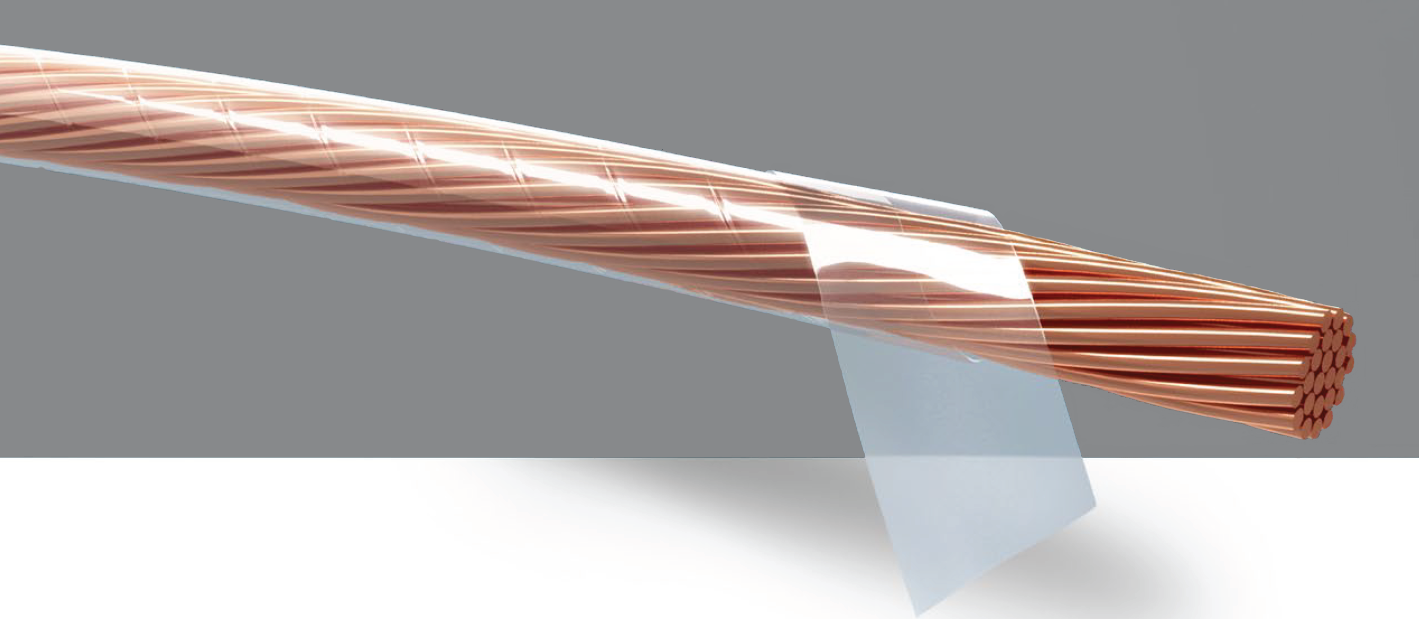

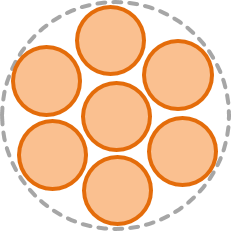

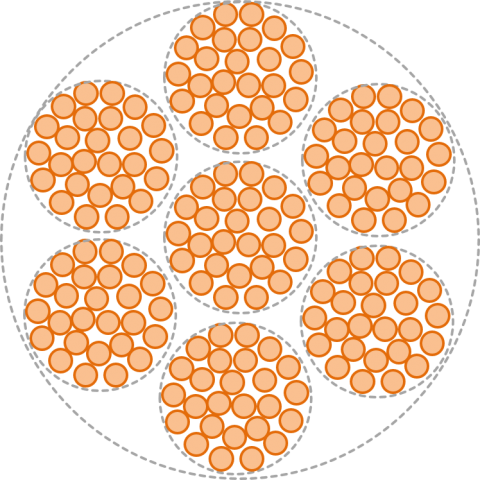

同心绞合利兹线

每股单线同心地围绕着利兹线的中心导体,并被排列在一层或多层中。在这种设计结构中,每股线在扭绞过程中自然地被引导到它预定的位置,从而使产品具有稳定一致的尺寸规格和功能特性。应力消除纤维丝可被用于同心结构利兹线的中心股。

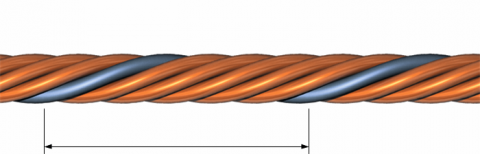

绞距

绞距是指单股线沿利兹线圆周(360°)旋转一周所需的距离。

绞距

绞向

绞向是指利兹线扭绞的方向。Z型是顺时针方向绞合。S型则与之相反,是逆时针方向绞合。

利兹线型号

益利素勒可生产范围广泛的高频利兹线,针对众多产品应用场合的不同需求,我们可提供多种类型的利兹线。

利兹线型号概述

下表显示了基本产品差异及其技术参考值的概述。要直接比较所选产品类型的特性,请点击下面的链接

EFOLIT®

对于需要强制认证以及高介电强度的安全相关应用,我们可供应至少有三层绝缘膜的的加强绝缘产品EFOLIT®-利兹线系列。该产品可提供F/155°C和H/180°C两种温度等级的高达1414 V峰值的工作电压。经VDE认证的严格生产过程监控保证了产品的连续的高性能水平。

三层绝缘挤塑利兹线

在利兹线外层用挤塑工艺包覆ETFE (乙烯-四氟乙烯共聚物),可在高电压环境下保证绝缘。三层绝缘挤塑利兹线具有非常好的柔韧性并且可以满足各种安规标准的加强绝缘要求。

独特的挤塑层的产品及工艺技术来自美国的Rubadue线材,并在益利素勒的中国杭州工厂合作生产,以便更好地在亚洲为特定的客户提供车载充电机和充电桩的应用服务。

应力消除利兹线

非常细的利兹线或对拉伸强度或弯折寿命有较高要求的利兹线可以用高强度单纤维丝或多纤维丝加强。为了获得最佳性能,这些高强度丝被放置在利兹线的中心位置。在通常情况下,只需将应力消除丝作为一个成束的非导电元件集成到利兹线中即可。

丝包利兹线

尺寸

尺寸规格

为了快速选择合适的利兹线,可以将过滤器用于下表中所有的利兹线特性。

为了简化您的搜索,您可以输入所有特性的最小值和最大值。例如您可以在标称电阻一列中输入最小值和最大值,从而得到满足这些标准的利兹线结构。

其他尺寸和结构可根据要求提供。

所有数据基于EN60317-11标准。

利兹线总电阻

给定利兹线结构的总电阻是由导体材料的电阻率、标称直径和股数、绞合步数、所选绞距和其他工艺的影响所决定。

单股线的电阻值可从益利素勒所提供的技术资料中查询。

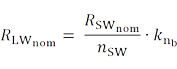

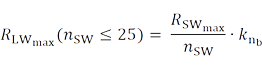

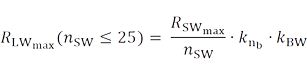

根据DIN EN 60317-11规定的方法,利兹线总电阻的计算公式为:

利兹线标称电阻

其中包含单股线标称电阻

和单线数量

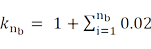

和用于补偿绞制过程中长度减小的影响的系数

绞合步数

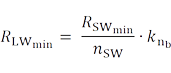

利兹线电阻最小值

其中包含单线电阻最小值

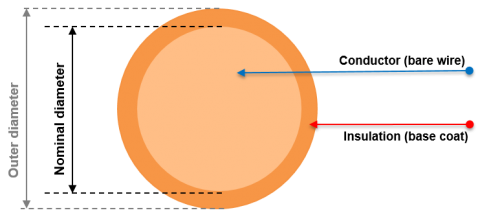

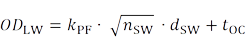

利兹线外径和截面积

标称外径取决于绞合方法(自由绞合/同心绞合)、绞合步数、绞向、绞距和单线的标称直径,也会受到某些过程因素的影响。

由于利兹线天然的柔韧性、弯曲的半径以及绕线张力相关的尺寸稳定性都会影响外径的测量结果,因此标称外径是依据测量的平均值来近似测定。

依据DIN EN 60317-11标准,利兹线标称外径的计算公式如下:

其中束绞系数KPF见下述表格

| 束绞系数 PF | |

|---|---|

| 单线数量 | 束绞系数 |

| 3 到 12 | 1.25 |

| 16 | 1.26 |

| 20 | 1.27 |

| 25 到 400 | 1.28 |

单线数量

单线标称外径

选择包覆层时外径的增加值

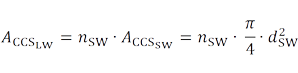

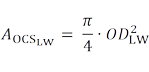

总截面积由利兹线外径计算值的平方得出。

填充系数

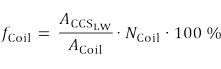

利兹线填充系数

利兹线填充系数指导体截面积与利兹线总截面积的百分比

其中包含产品和工艺系数

填充系数取决于单线标称直径、绞合步数、绞距、绞向、绝缘层厚度以及其他工艺参数影响。

如果导体截面积固定不变,则填充系数会随单线直径变细而减小。这是因为随着单线直径变细,线材间的空隙面积会增大,利兹线的外径和总截面积也会随之增加。

如果利兹线外径固定不变,填充系数也会因单线直径变细而减小。因此这时导体截面积会随之减小。

下图显示了在导体截面积固定不变时填充系数与单线直径之间的关系。

图

显示利兹线的外径随单股线标称直径的增大而增大。

图

说明了随着单线标称直径的增大,铜导体填充系数随之增加。

如果将利兹线由圆形压成方形,则填充系数将增加,请参考图

中的绿色曲线。

在这种结构下,邻近绕组间的距离更近,因而线圈填充系数更大。建议选择直径大于0,100毫米(38 AWG)的单线。因为利兹线的单线直径越细,吸收机械应力的性能就会越弱。

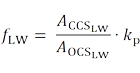

线圈填充系数

线圈填充系数取决于利兹线填充系数和束绞系数。

使用定型利兹线的线圈优化的填充系数 如下图所示

电磁学原理

高频利兹线损耗的计算

高频损耗由各种损耗因素的累积影响,以及利兹线应用的工作条件所决定。因此无法用一个简单的公式进行计算,必须依靠对应用的深入理解和一些额外的工具。

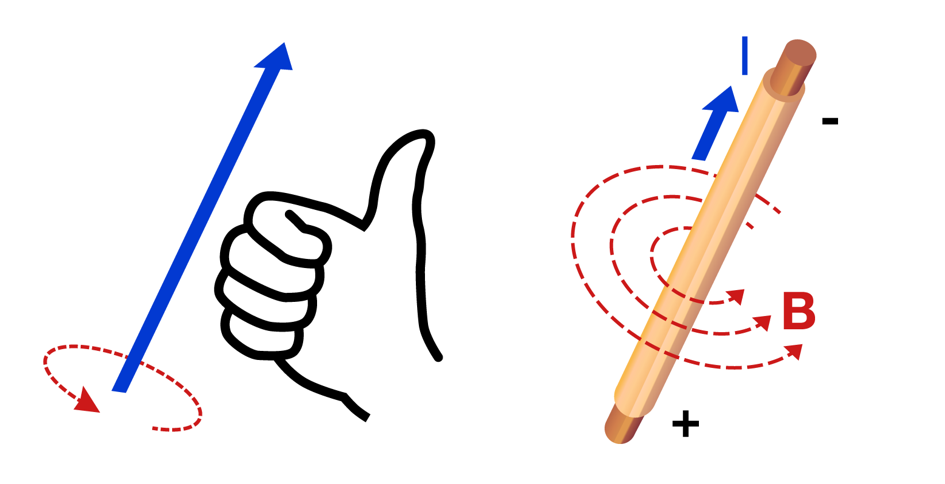

右手定则

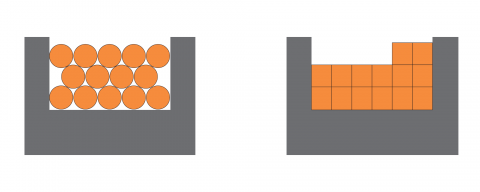

A电流I流过直导体会产生磁场B,其磁力线同心分布在导体的周围。如果用右手握住直导体,大拇指指向电流I的方向,则四根手指所指的为环形磁场B的方向。B也被称作磁感应强度,与磁场强度H和材料的介质磁导率µ成正比:

在磁场恒定的情况下,真空磁导率计算如下

相对磁导率是特定介质的磁导率与真空磁导率之比

请参考下图“右手定则”说明

交流电阻/直流电阻比率 X/R

RAC/RDC

线圈的综合电阻定义为阻抗Z=R+jX,这是一个矢量,由电阻R代表实部分量和阻抗X代表虚部分量组成。

T随着频率的增加,电流越来越沿着导体表面流动。测量到的交流电阻X,也称为RAC将上升。与之相对的是直流电阻R,也被称为RDC,随着电阻值增大,通过交流电阻的欧姆损耗将增加,在高频下甚至可以超过直流损耗。

X/R因子,通常也被称为RAC⁄RDC因子,是交流电阻与直流电阻的比值(X/R ≥ 1),也是利兹线高频性能的一个指标。在给定利兹线结构的大多数情况下,X/R因子可被准确地测量或计算。根据相应的频率范围,其典型值一般为1-12。除了正确选择单线直径外,利兹线结构设计也有着同等重要的地位。

图表

显示具有相同的导体截面积的五种不同利兹线结构在不同频率下的RAC/RDC曲线。图表显示,随着频率和单线直径的增加,交流电阻和高频损耗也将增加。频率为1 MHz时,单线线径为50 µm的利兹线结构效果最佳。不过1.29的RAC/RDC因子仍明显高于1.0的最优值。在这种情况下,首选的改进可能是选择较小的单线直径以及优化的绞合结构。

线圈品质因数

品质因数Q是衡量一个振荡的电气或机械系统的损耗的自由度。

例如较高的品质因数表示谐振能量损耗的速率较小,振动衰减得比较慢。一个装有高品质轴承的单摆在空气中运动,其品质因数较高,而浸在油中运动的单摆的品质因数则较低。

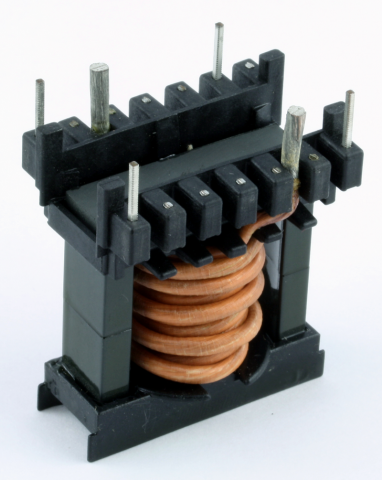

一个电子谐振电路由空气线圈 (电感 L)、电容 (C) 和欧姆电阻 (R)组成。品质因数Q测量的是谐振总能量与其能量损耗之间的关系。高品质系统的一个重要条件是使用高品质因数的线圈。

线圈的基本损耗因素是其电阻RL,电阻RL将受到趋肤效应和邻近效应的影响并随频率的增加而增大。

品质因数的一般关系可以被描述为

不同影响因素的相互干扰,使得线圈品质因数Q的变化趋势受到频率影响。这些因素包括:

线圈频率 f [Hz]

线圈的品质因数Q随着频率的上升而增加,到达某个点时由于高频损耗的不均衡性增加而再次减小。通过利兹线结构(单线股数、标称直径、绞距)的调整来增加品质因数是可行的。

线圈电感 L [H]

线圈品质因数Q随着电感的增加(例如随着匝数N的增加)而增大。在较高的频率下,增加的线圈电阻损耗R会带来负面影响而削弱这一效应。线圈的固有电容随着匝数的增加而增大。

与频率f相关的线圈电阻R [Ω]

线圈的电阻损耗受导体总截面ACCS的影响。R的减小最初会导致品质因数增大。但频率较高时,由于高频损耗的增大,品质因数迅速降低。

通过利兹线结构(单线股数、标称直径、绞距等)的调整来增加品质因数是可行的。

图表

显示通过测量3种不同结构的匝数为12的睿智绞线平面线圈,利兹线和线圈的结构对品质因数的影响。

通过减小绞距到10mm(图表上的红线),相比蓝色实线的绞距26mm,能在整个频率范围之内增加线圈品质因数。如果只需要在选定的频率范围内增加线圈品质因数,如本例中150 kHz以内的范围,即便是长绞距的结构仅通过使用更多绕组匝数 (本例中从12 增加到17)来增加电感L就可以达到目的。因此在选定的频率范围内品质因数增加,但在更高频率时品质因数快速下降 ,请比较蓝色虚线与红色实线。

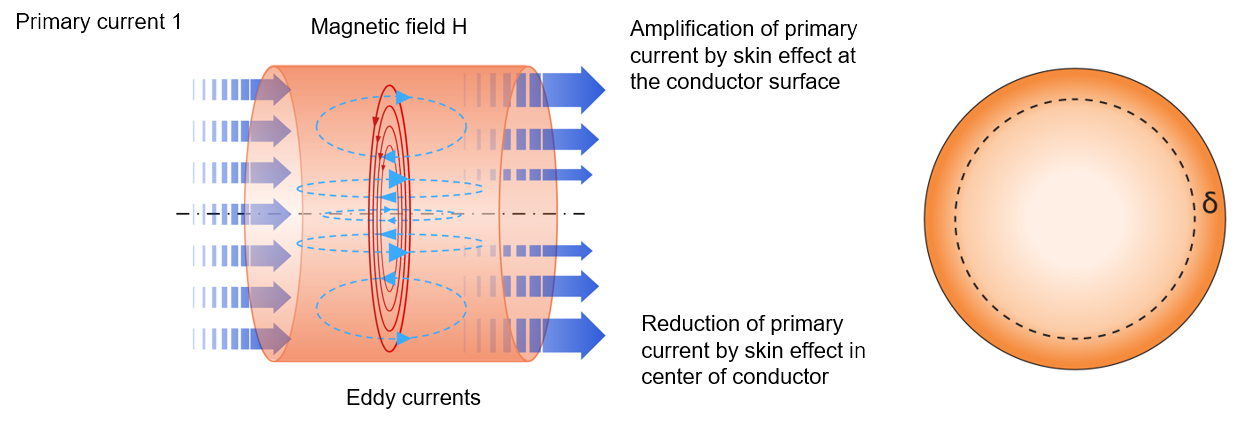

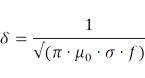

趋肤效应和趋肤深度

电流在导体内部和外部都会产生同心磁场,如下图所示的磁场强度H。

在导体内部的磁场会产生干扰的同心涡流,影响电流流向导体外表面区域。频率越高,其影响越大。该效应使得电流的趋肤深度δ减小。趋肤深度δ是指导体中电流密度减小到振幅的1/e(e = 欧拉常数)处的深度(如下图)。这样,导体的欧姆电阻就与频率相关并随着频率的增加而增加。因此,热损耗的增加也就会导致导体电阻相应的升高。

趋肤效应的这个简化公式只适用于趋肤深度δ小于等于最小圆导体直径的三分之一或小于方形导体的四分之一的场合。

其中

μ0 真空磁导率

σ 导体材料的电导率

f 流经导体的电流频率

下表显示了趋肤深度与频率的关系。

| 频率 f | 趋肤深度δ (铜) |

|---|---|

| 10 kHz | 0.66 mm |

| 50 kHz | 0.30 mm |

| 100 kHz | 0.21 mm |

| 500 kHz | 0.094 mm = 94 µm |

| 1 MHz | 0.066 mm = 66 µm |

| 10 MHz | 0.021 mm = 21 µm |

| 100 MHz | 0.0066 mm = 6.6 µm |

更多的高频损耗也由外部和内部的邻近效应引起。

邻近效应

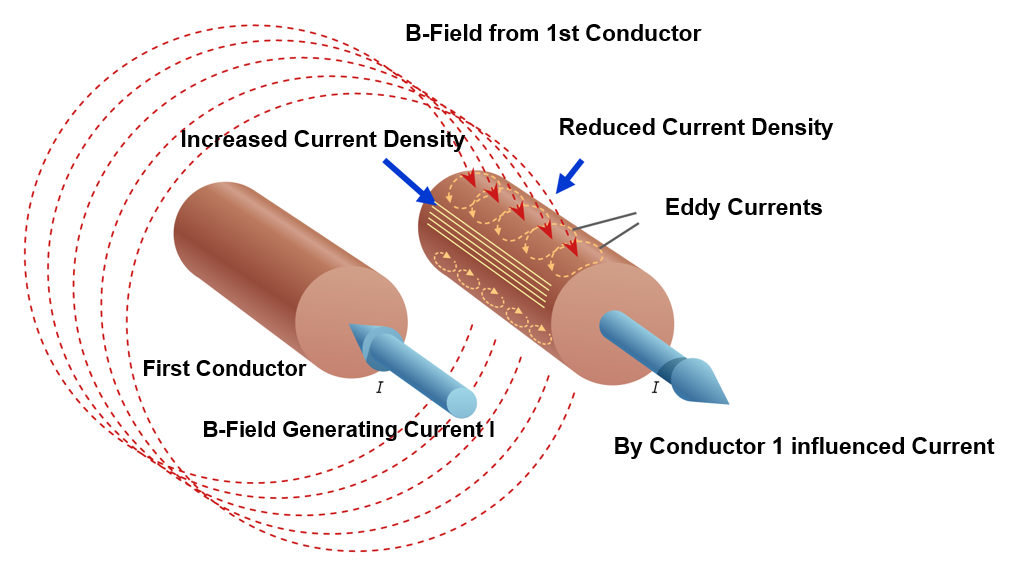

外部邻近效应

相邻导体或其他电气元件中交变磁场的影响也可以引起电流偏移的效应,请参考图解“外部邻近效应”。

与趋肤效应引起的涡流不同,外部邻近效应引起的涡流并不以第二导体为中心旋转对称。这是因为第一导体的交变磁场是由外部电流通过第一导体产生的。

引起的涡流方向在受影响导体上的任何位置几乎是一样的。这里的涡流也会引起电阻损耗,从而导致和前面部分讲到的趋肤效应的一样的欧姆电阻的明显上升。产生这些涡流所必需的能量是由外部电流引起的磁场所提供的。由于涡流和产生它的磁场之间的干扰,在任何其他相邻的导体中也会引起额外的高频损耗

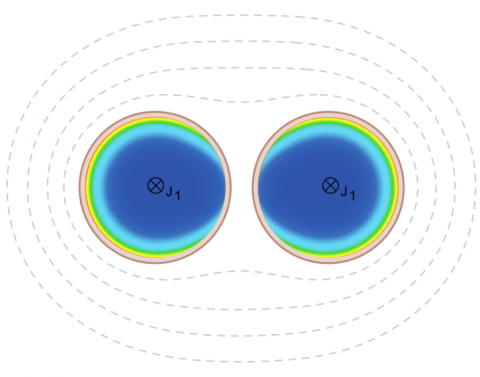

内部邻近效应

利兹线内单股线的交变磁场将会在邻近的单股线中产生涡流,从而引起损耗。因为这些磁场由内部的单股线产生,所以称之为内部邻近效应,形式上类似于趋肤效应,其电流偏移见下图。

由内部邻近效应引起的电损耗会随着频率的升高而增加,在某些情况下,甚至会超过具有相同直流电阻的实心导体的损耗。

图片“内部邻近效应”显示了相邻单线之间电流的不均匀分布(电流密度从蓝色到红色增加)。

这一效应表明利兹线存在最佳的频率范围以使其电气损耗低于实心导体。超出此范围,使用多股单线的利兹线会有负面影响。

在考虑导体的高频损耗时趋肤效应和邻近效应是最重要的因素,其中内部和外部邻近效应的组合影响占主导作用。对于指定的工作频率,在大多数情况下只有利兹线结构可以帮助减少损耗。这时利兹线的结构参数,如单线股数、单线直径、绞合步数、绞距和绞向都必须根据具体的应用来确认。同时要注意,规定的长度内每股单线都在利兹线截面积上占有自己固定的位置,因此每股单线可以保持同样的长度和电阻。本文中由漆包单线绞合而成的利兹线被称为高频(HF)利兹线。

单线直径和频率范围的关系

高频利兹线的设计和结构及其产生的电气性能取决于许多因素。采用不同的设计方案可以获得相近的性能参数,但需要根据经验来正确定义利兹线的结构,以保证产品可以被经济和稳定地生产。因此,对于每个特定的应用,正确选择单线直径是非常重要的考虑因素。

高频利兹线损耗的计算

利兹线参数的选择

利兹线设计 - 涉及以下几个方面 :

I 利兹线特点:结构参数的主要影响

II 单线标称直径的选择

III 利兹线结构的选择

IV 实例:用于高频层绕线圈的利兹线

V 比较:根据Charles R. Sullivan的方法进行预选

I 利兹线特点:结构参数的主要影响

利兹线性能取决于其电气、机械、耐热和化学特性。耐热和化学特性要求可通过选择合适的绝缘材料实现,而电气和机械特性则主要取决于绞合结构参数的选择。

下表

概括了利兹线结构参数对其最重要的电气和机械特性的影响。

表格

显示了与典型高频线圈相关的利兹线特性的概况。

每一种应用中,经常会存在一些相互冲突的要求,需要益利素勒和客户予以周全地解决。依靠益利素勒在利兹线设计和结构方面的专业知识,并根据客户对产品性能的要求,最终可以使成品在性能、工艺和成本方面得到最佳的组合。

II 单线标称直径的选择

正确选择单线标称直径是利兹线设计中最重要环节之一,因为这将直接影响利兹线性能 (请参考

),同时也影响所有机械特性。

单线直径和工作频率以及趋肤深度之间的关系请参考表格

总体而言,工作频率越高,所需的单线标称直径越小。考虑到利兹线内部子束直径 ODBundle与趋肤深度δ间相互的影响,作为简化处理,最大单线直径应小于等于δ的三分之一:

例如:

f = 200 kHz

δ ≈ 0,172 mm

ØSW ≈ 0,063 mm

对于导体总截面积相同的各种利兹线之间机械性能的差异,基本上可以认为:

单线标称直径越小

- 利兹线越柔软

- 最小弯曲半径越小

- 柔韧性越高

- 利兹线总外径越大

- 利兹线填充系数越小

- 单线成本越高

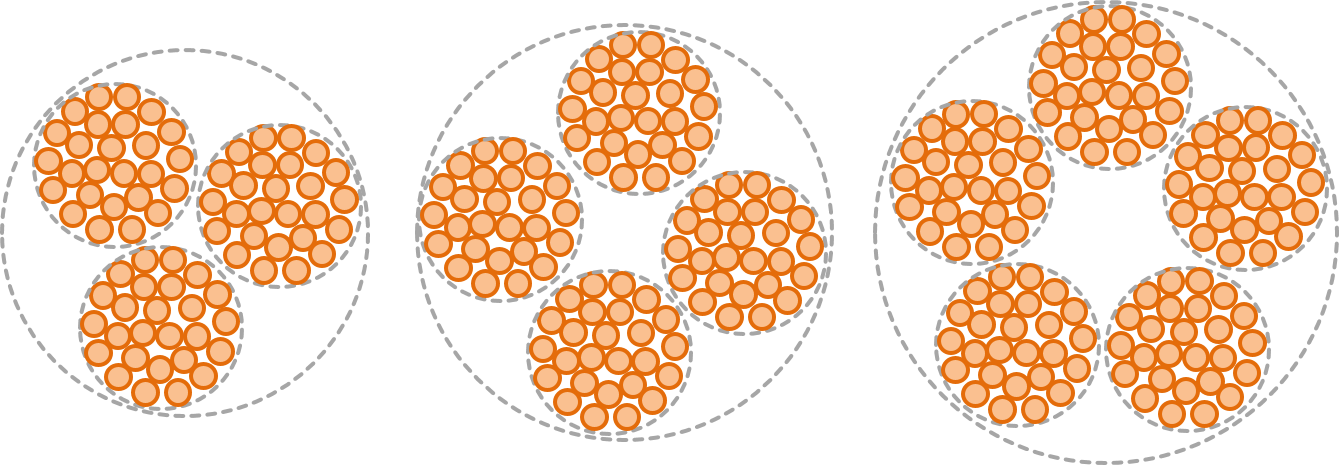

III 绞合结构的选择

当利兹线的单线股数已确定,就可以选择具体的利兹线结构。股数较少(一般< 60)的细线可以用一步绞合,股数较多和较粗的利兹线则需要用多步绞合。

绞合结构由绞距、绞向(S 或 Z)、股数和绞合步数所确定。合理选择绞合参数可以确保最优的电气、机械和工艺方面的

股数和绞合步骤

导体总截面积、电阻或电流密度等参数决定了所需的单线股数,然后可以分解成若干束数和绞合步数。考虑到这些因数,可以通过选择第一步绞合的股数以获得最佳的高频性能。并且每一束的单线股数通常小于60。

最终绞合步骤通常有4种基本的绞合结构:3束、4束、5束和同心7束绞合结构。

3、4和5束结构

这些结构具有良好的绞合性能,单线在利兹线截面上分布均匀,可以优先用于需要优良高频性能的场合。其中,5束绞合结构的束数较多,由于其圆度随着束数的增加而提高。

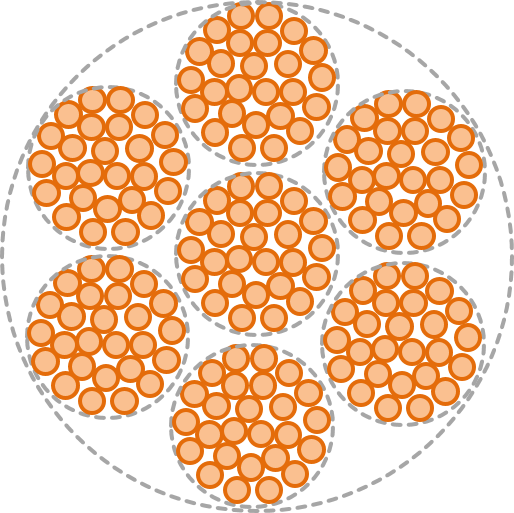

7束结构

这一同心结构也被称为“1+6束”,同时具备高柔韧性以及良好的尺寸稳定性和圆度。由于其中一束线始终位于中间,不同束的总电阻不同,因此这种结构不太适用于要求最佳高频性能的场合。为了弥补最后的绞合步骤中线束的长度差异,中间线束的绞向与外围线束的绞向相反。因此中间线束的绞向总是代表最后绞合步骤的绞向。

根据绞合的步骤以及电气和机械的要求,如前所述的这些基本结构可以互相结合。特殊结构也是可以提供的。

绞距和绞向的选择:

绞距决定了线束的紧密度和高频性能,单步绞合紧密度可以用绞合系数来衡量,它等于绞距和线束外径的比值并通常在15 mm -20 mm之间:

绞合系数

绞合系数fB计算如下

根据绞向,在前面的绞合步骤中通常选择较高的绞合系数。

对于绞距和绞向的选择,基本上可以认为:

绞距越小,

- 绞合结构越紧密和坚硬,尺寸稳定性越高

- 线束外径越大

- 如果想要获得最佳的高频性能,需对所有绞合步骤中的绞距作最优的选择和组合

- 对于复杂的利兹线结构,如果需要较高的机械柔韧性,优先为每步绞合选择相反的绞向

- 绞距应该小于线圈的最小绕组直径

表格

显示了270 x 0,071 mm利兹线的不同结构设计和其特性。

IV 例:层绕高频利兹线圈

在多数情况下,高频线圈采用匝数较少的层绕方式绕制。通常这些利兹线会用天然丝或尼龙丝包覆,以使线材在一定的绕线张力下仍能在线圈骨架上保持圆形,这样才能实现准确的分层绕线。在某些场合也可以使用无包覆层的利兹线(

),这时特别需要注意的是选择紧密和尺寸稳定的结构。然而利兹线会不可避免地发生小的椭圆变形,因此需要适当地减少线圈总外径来作为补偿。所以在线圈最大外径一定的情况下,有包覆层的利兹线比无包覆层的利兹线具有更高的导体截面积。

例子

我们以一个30匝的工作频率为200 kHz的层绕利兹线圈结构的简单选择过程来举例,假定绕组截面的有效尺寸宽度 ×长度 = 25.8 mm x 8.0 mm.

绕组结构

根据不同的绕线技术,层式绕组的结构可以是每层匝数相等或者交错。在预选时,可以大致按照每层匝数相同的情况来计算。这样绕组可以排列成3层,每层10匝。利兹线最大外径 dLW=25.8 mm ⁄ 10 = 2.58 mm.

单线直径

工作频率越高,单线越细。同时,随着标称直径dSW的减小,不但单线成本会增加,而且绞合工序的成本也会因更复杂的绞合结构而增加。考虑到子束的直径与趋肤深度δ之间的相互影响,大致可以把dSW ≤ δ/3作为单线直径选择的规则。在实践中,这是在频率特性和成本之间获得折衷的做法。根据不同的应用和技术要求,相应的变动也是允许和正常的。

在本例中,第一步选择单线标称直径dSW= 0,063mm就已足够(请参考上述第二节中的例子)。

绞合结构

利兹线总外径的选择取决于绕线过程中绞合线材的尺寸稳定性,考虑到这一因素,利兹线最大计算外径(如上所述dLW =2,58 mm)实际选用的经验值对于有包覆层的利兹线应减少10% (到dSW =2,32 mm),而对于无包覆层的利兹线应减少15-20% (到dSW =2,19 mm)。

无包覆层的利兹线应绞合得更紧密些,这意味着每步绞合时使用更小的绞距。优先考虑4束或5束绞合结构。

在50kHz, 125 kHz和 200 kHz工作频率下,以绕组截面: 宽 × 高 = 25,8 mm × 8,0 mm为例, 表格

显示了有包覆层和无包覆层的利兹线结构的对比。

在本例中,可以看到对于层式绕组

- 相比普通利兹线

- 导体填充系数较小,无包覆层利兹线的单线股数可以更多,导体截面积会更大。

- 绕组窗口的导体填充系数通常在25-30%的范围内,相比无包覆层的普通利兹线,有包覆层利兹线的填充系数更高,因为其导体总截面积更大。

- 单线数小于60的5束绞合结构可以使利兹线更对称。

如果线圈可以自由绕制而不必要采用层式绕组,则有可能使用非常柔软的利兹线。在这种情况下,线圈绕组彼此紧贴,中间的空隙被尽可能地填充,绕组截面的导体填充系数可以进一步地增加。或者也可以使用

, 必须保证设计的导体截面积在应用中满足所需的载流量。

V 对照: 根据Charles R. Sullivan的方法预选

美国达特茅斯赛耶工程学院的Charles R. Sullivan在他研究的

中提出了射频线圈利兹线的简化预选方法。

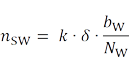

所使用的参数包括趋肤深度、工作频率、绕组截面匝数、绕组截面宽度及其所需的计算常数K。用该方法可以选取多种合适的利兹线结构,包含单线标称直径、第一步绞合的最大单线股数和多步绞合的束数。

预选通过以下步骤来完成 :

1. 根据导体电阻率ρ、工作频率f和磁导率µo计算趋肤深度δ。

2. 根据线圈结构确定绕组截面有效宽度bW和所需的绕组匝数NW,如果需要也可以选择有空隙的结构。

3. 根据几种单线的标称直径dSW,计算总单线总数nSW的近似值,每种单线的实际股数与计算值之间可能有±25%的偏差。

4. 单线标称直径和单线股数的选择完成后,根据绕组匝数与绕线截面的匹配来确定单线直径(和股数的最佳组合),在这里假定绕组截面导体填充系数为25-30%。关于利兹线电阻和载流量的要求必须要明确,采用更粗单线的其它结构也是可行的。

5. 趋肤深度和子束直径之间的相互影响需要被考虑在内:第一步绞合的最大单线股数nSW1max 取决于受频率影响的趋肤深度δ和选定的标称单线直径dSW。

6. 根据(3)计算得出的总单线股数需要分解成若干子束并通过若干绞合步骤来完成,其间可以采用3束、4束和5束绞合结构的组合。

这里对绞合结构的绞距或绞向不作推荐,留待利兹线制造商确定。

表格

较分别按照益利素勒经验算法和Ch. R. Sullivan方法选择的利兹线结构,对比采用层式绕组线圈,绕组截面为25,8 mm × 8 mm,工作频率分别为50、125和200 kHz。

表格显示用经验方法选择的利兹线结构与用Sullivan方法选择的结果十分接近,两者都包含了一些共同的基本建议:

- 用经验法选择的单线总股数都在Sullivan建议的范围内。

- 3束、4束或5束绞合结构的组合应用是益利素勒典型利兹线设计的重要组成部分(参考表5)。

- 第一步绞合时子束中的单线与绞合结构是相互独立并没有关联的,益利素勒通常选择每束不超过60股的单线(参考表5)。

- 为降低成本而采用比较粗的单线(dSW≤ δ/3)来设计结构是可行的(参考表5),Sullivan推荐的相应子束内单线股数为36至64之间。

- 除降低成本以外,采用这些结构还可以增加利兹线和绕组截面的填充系数(参考表5)。

- 通过细心选择绞距和绞向,可以为每个特殊应用选定最优的产品。

综上所述,益利素勒使用的高频利兹线设计通常都涵盖了理论和实践两方面的要求。

利兹线工艺

利兹线连接技术

利兹线的连接技术往往具有挑战性,表格

推荐了通常适用的连接技术,表格只对最重要的影响因素作了列举,其它如漆型、单线绝缘厚度、包覆绝缘材料的耐热性、子束结构(紧密或松软)等因素未作考虑。

如需要合金利兹线连接的信息或有任何其它疑问,请联系我们。

利兹线绕线张力的确定

表格

列出了单股线的最大适用绕线张力。利兹线的最大绕线张力可以通过单线股数乘以单股的适宜绕线张力来计算。不论计算的数值,对于直径大于5mm的利兹线,建议的张力极限对于硬金属为420N,对于铜和较软的金属为270N。

这些数值是参考值,根据生产工艺的不同可能会有较大的差异。

线轴

不同的线轴类型可以选择不同的包装材料。在选择线轴时,要与客户密切合作,考虑客户的生产过程以及线轴类型的可获得性。

如欧洲和美国等西方国家与亚洲国家使用不同的利兹线线轴型号。

可供的线轴类型可从下面的表格中获取。

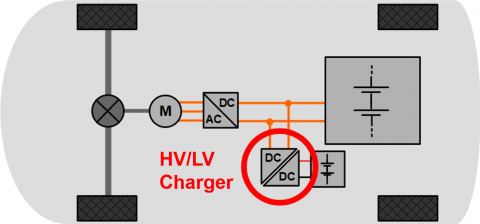

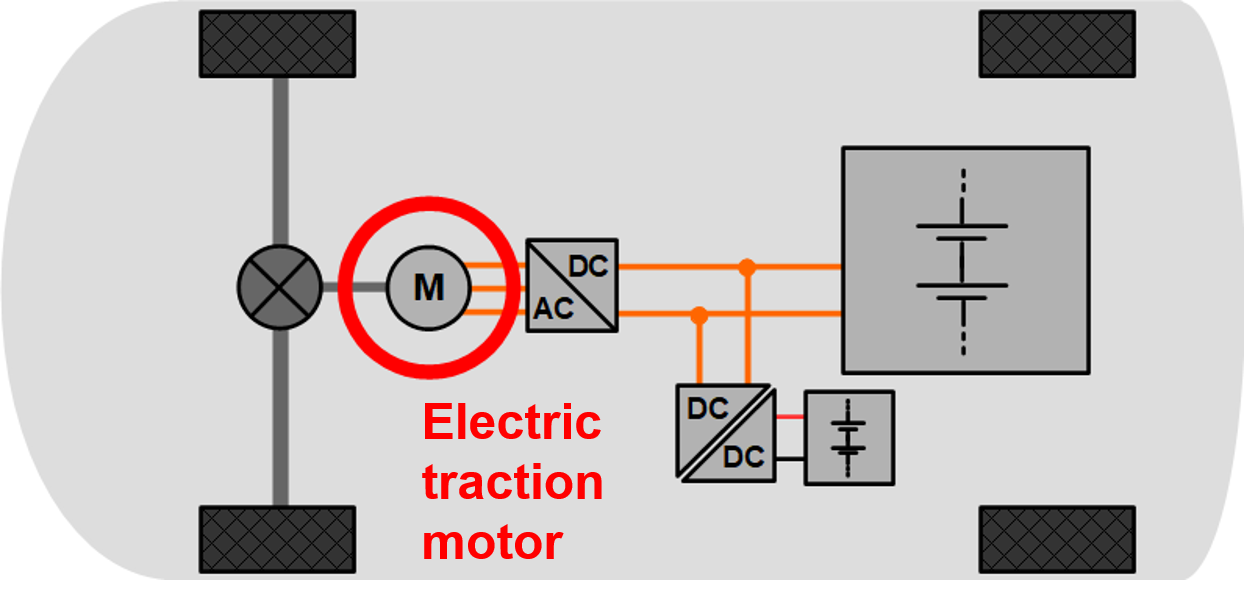

汽车工业

为应对全球对零排放汽车日益增长的需求,汽车企业纷纷投入巨资开发电动汽车。益利素勒作为开发创新电动汽车充电组件顺理成章的合作伙伴,目前已经在为当今的主要供应商提供技术支持和利兹线。今天,由于市场对更快充电时间和更高效率的日益增长的需求,需要富有创造力的利兹线解决方案,因此开发工作始终在继续。

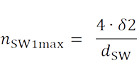

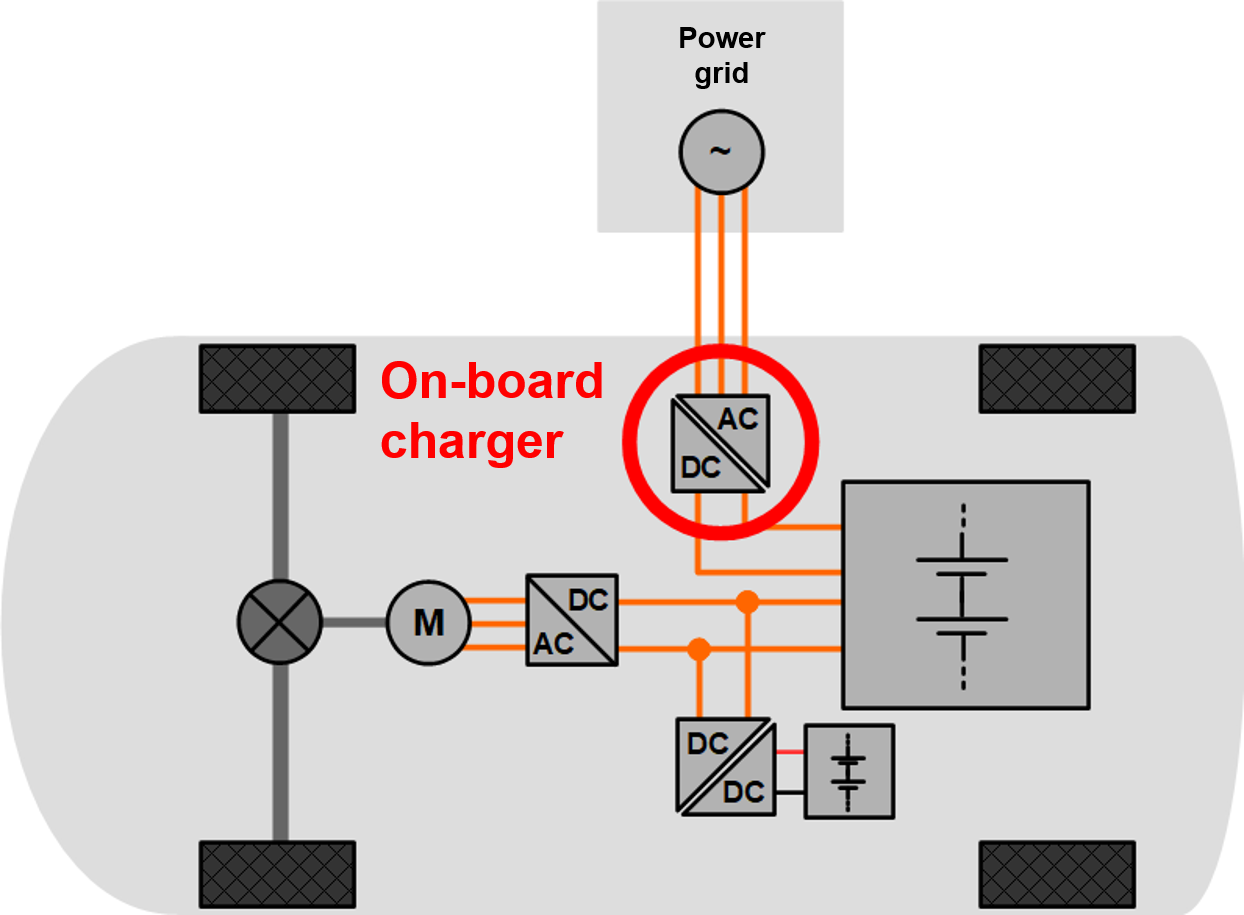

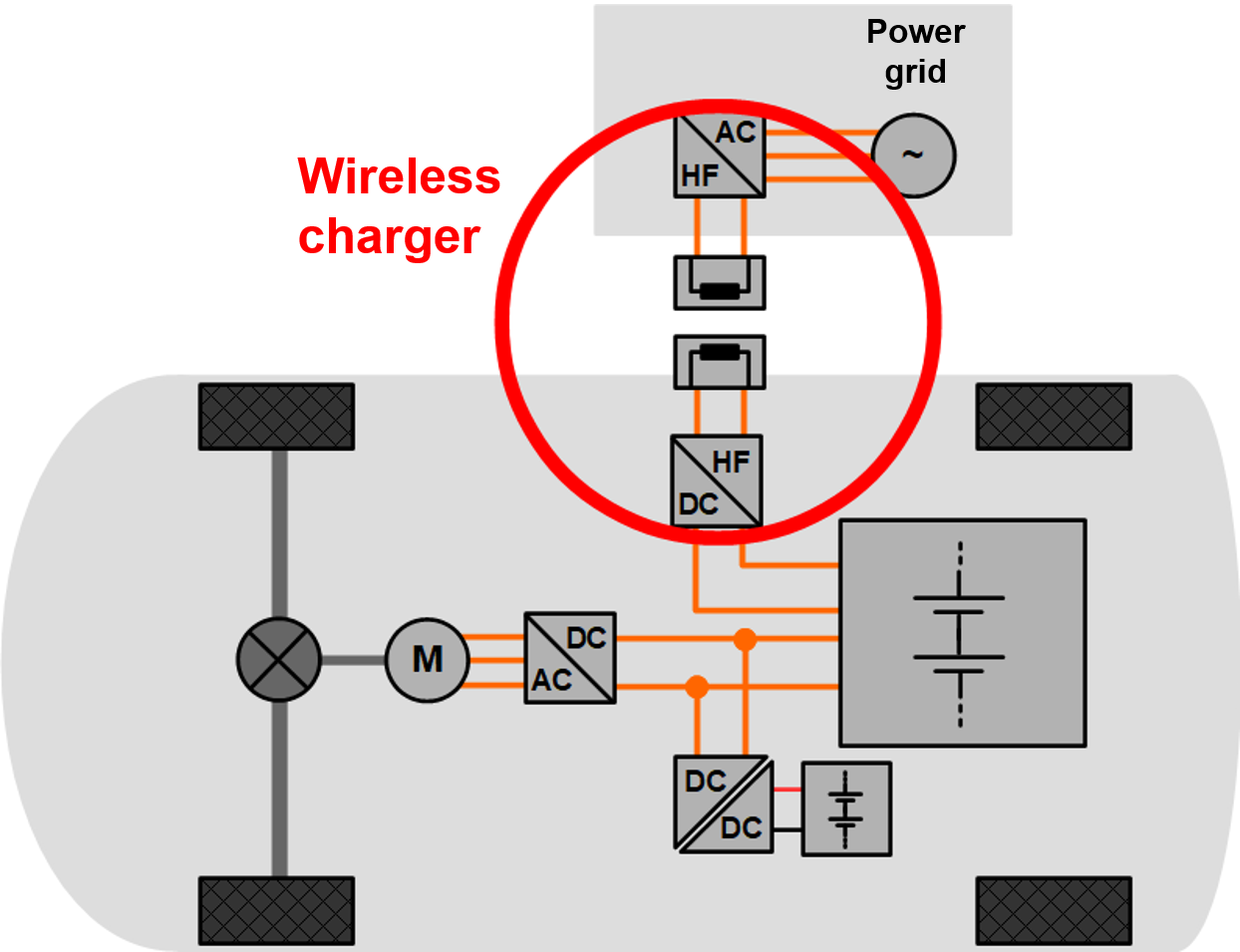

包含利兹线的电动汽车部件

- 车载充电机 (OBC)

- DC/DC 转换器

- 无线充电器 (WC)

- 充电桩

- 电机

为提高效率,降低在高频时铜损耗,以上部件必须要使用利兹线。

使用高频利兹线可以提升效率,使更高的功率密度成为可能。还可以使用更轻、更便宜的结构,从而增加电动汽车的电池续航里程。此外,通过节省材料降低生产成本也是可能的。

益利素勒提供范围广泛的利兹线产品,作为某些电动汽车部件的核心材料和决定性因素,参考以下章节介绍。

车载充电机 (AC/DC)

概述

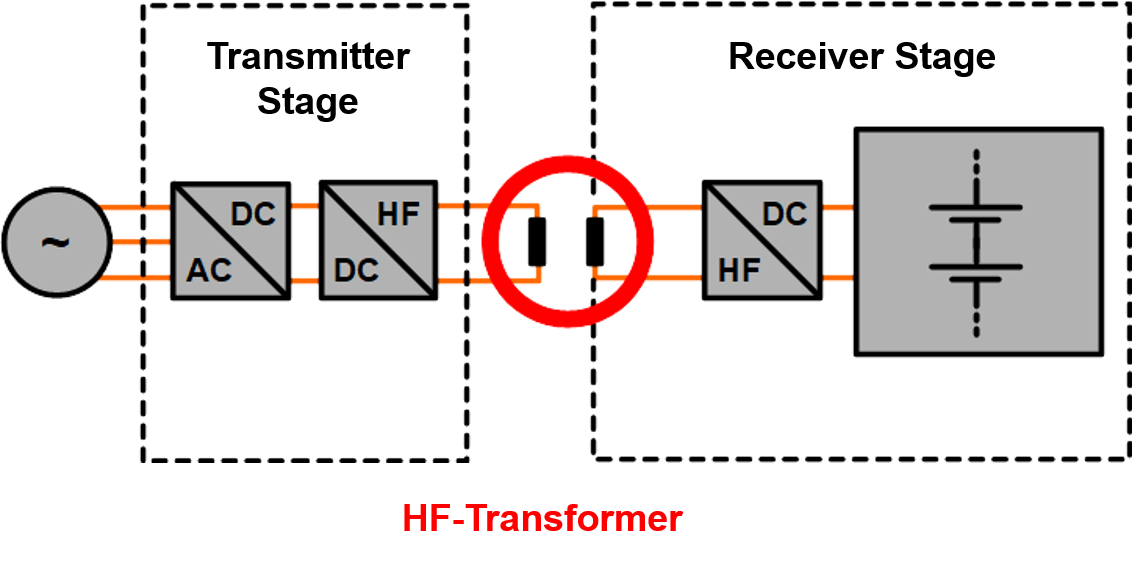

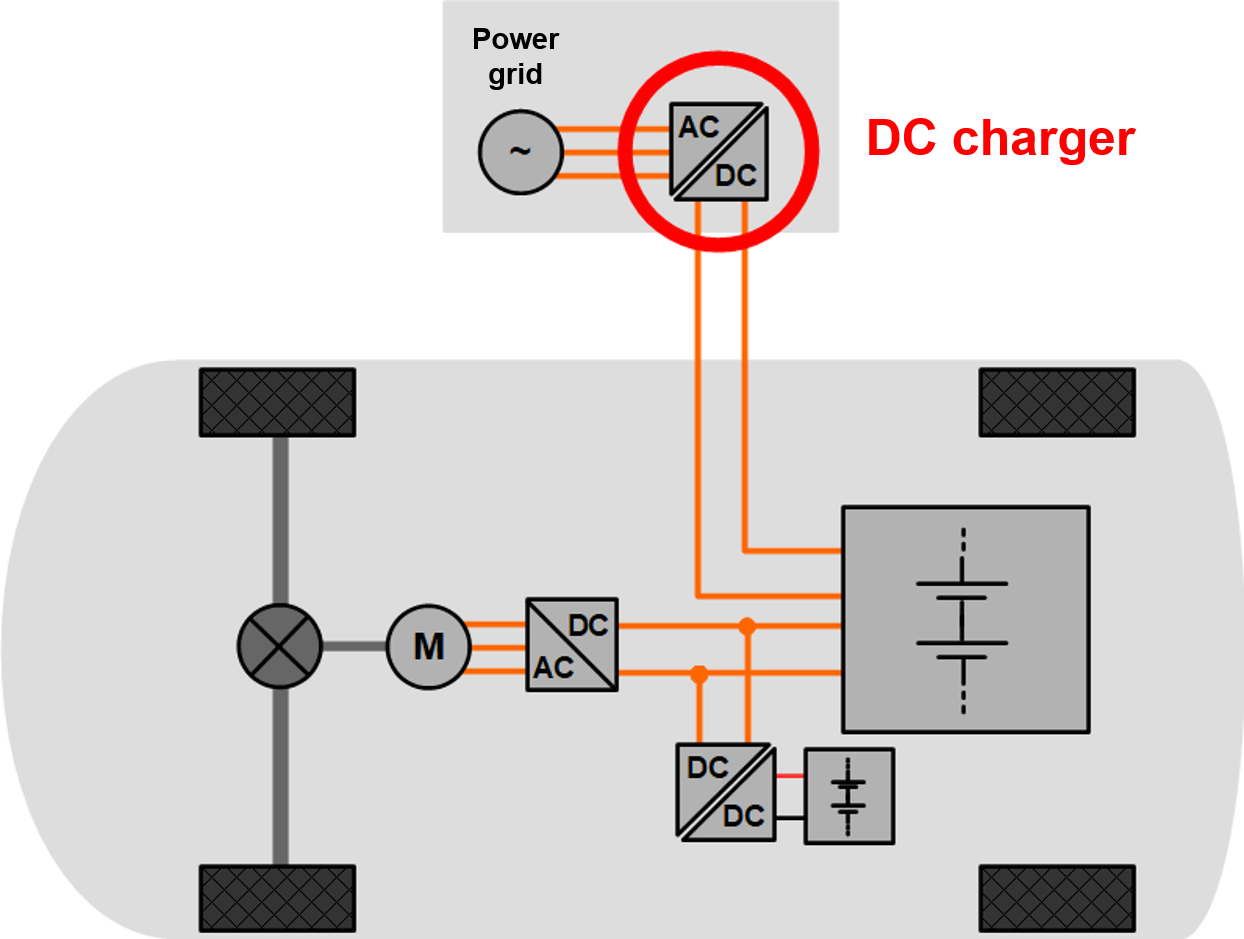

车载充电机 (OBC) 将电力从电网转移到动力电池,充电机在充电时将交流电转化为直流电。

如果使用外部高压直流充电器,则不需要通过车载充电机。

输入电压是由本当地电网结构决定的,参照下表相关参数:

| 输入电压(全球) | |

|---|---|

| 85V - 275V | 单相交流电 |

| 400V | 三相交流电 |

| 输出电压 | |

| 170V - 800V | DC |

车载充电机技术细节

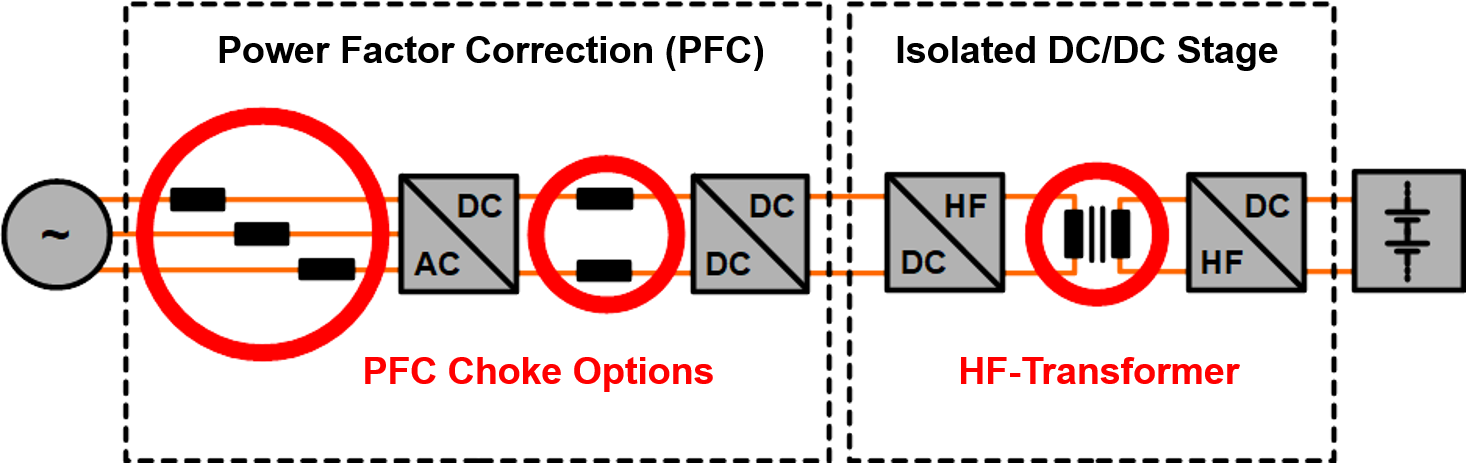

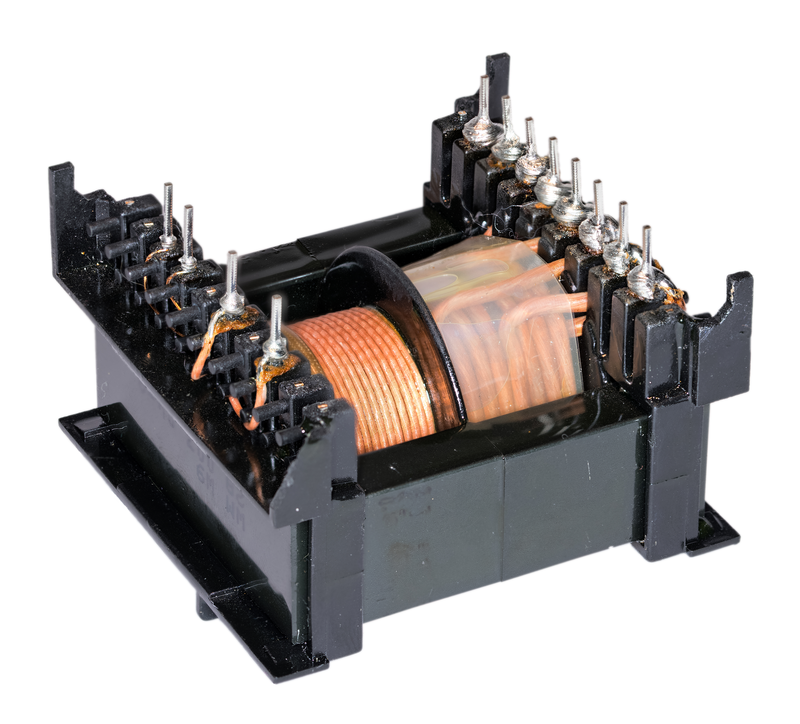

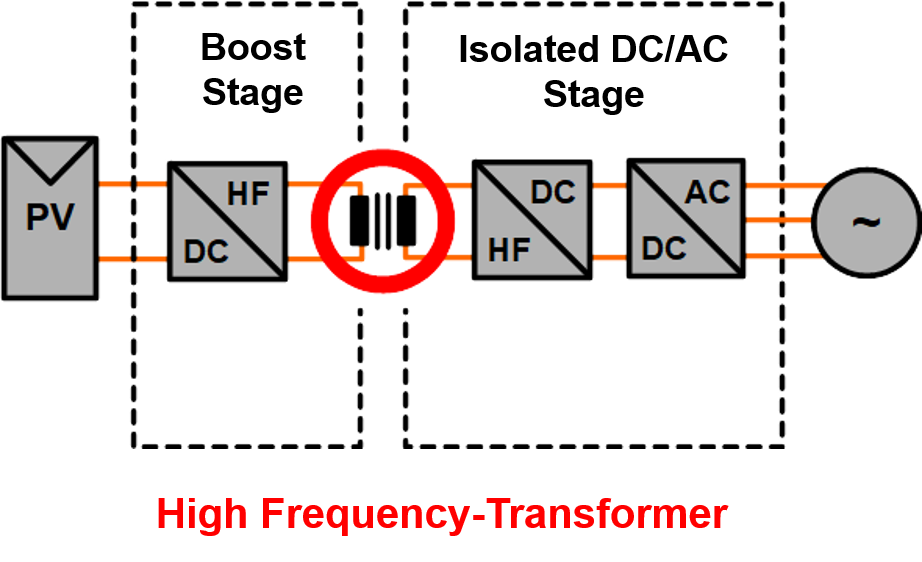

车载充电机主要由功率因素校正级(PFC)和DC-DC转换级组成,如上图所示。

在这些级的前后,需要用到两个用于电磁兼容(EMC)的静噪滤波器。

功率因素校正级

PFC级确保了来自公共电网是正弦的电流。

由一个升压转换器完成功率因素校正。

在这部分用到的效率相关器件是高频线圈,根据拓扑结构可以用单线圈或双线圈。

典型的开关频率低于 50KHZ。

益利素勒可以优化所有用于车载充电机的利兹线,使其达到最高的效率。

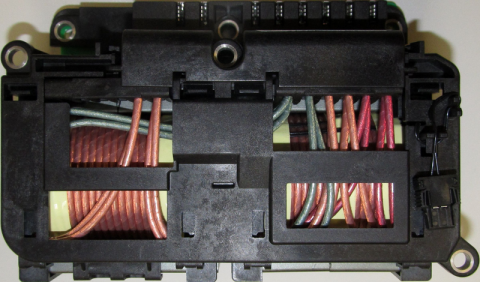

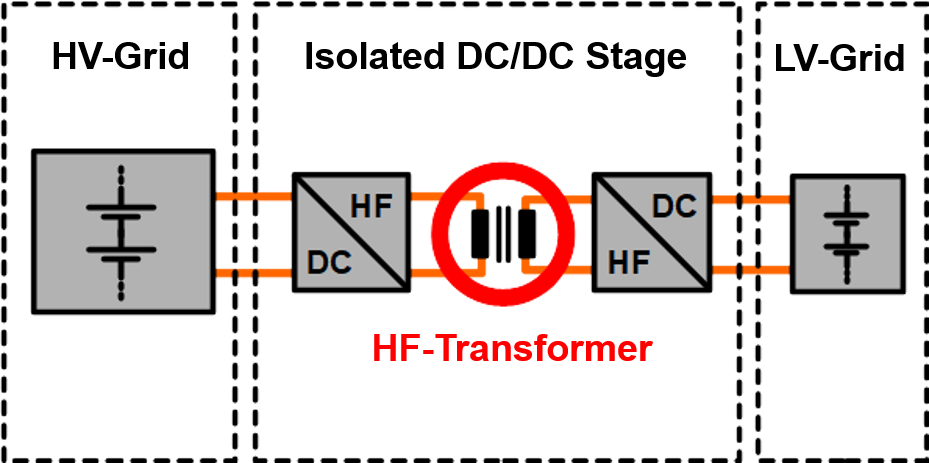

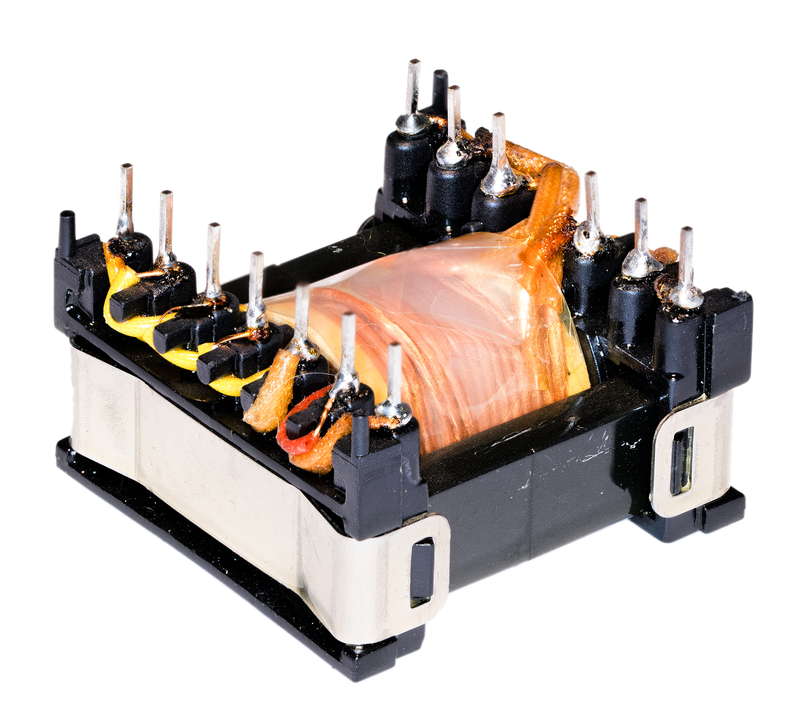

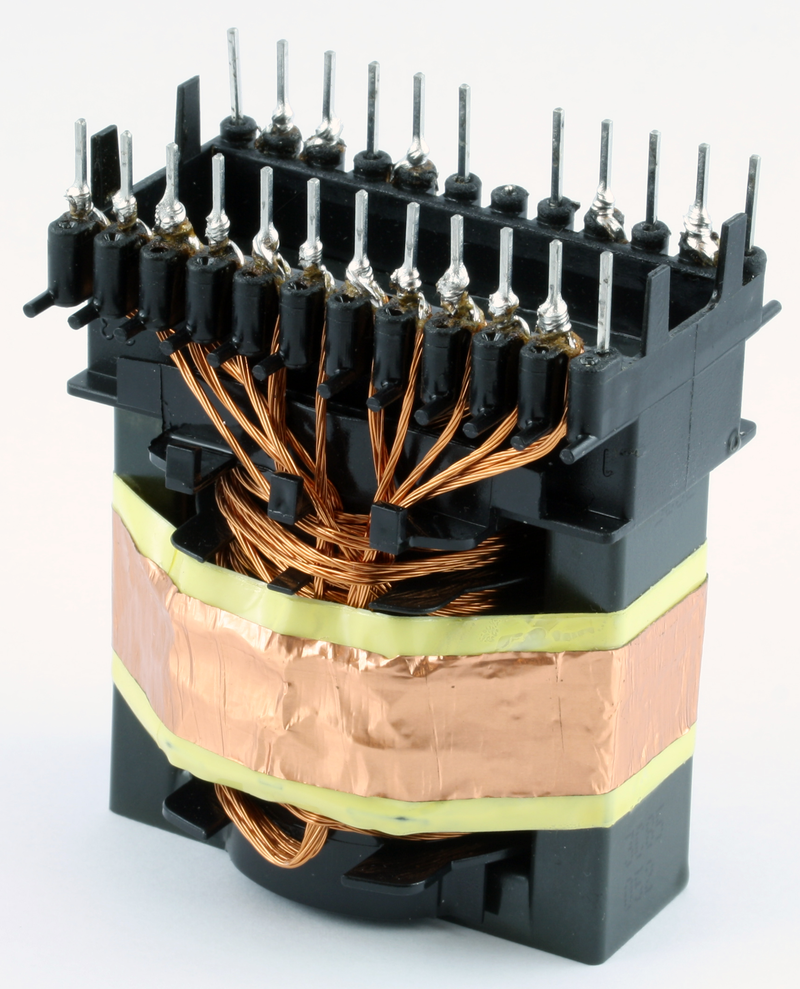

高压DC-DC转换级

主转换器通过电流隔离变压器传输能量。这种高频变压器是车载充电机的关键元件。它通过空气间隙将所需要的电能从初级转移到次级,具有非常高的效率。

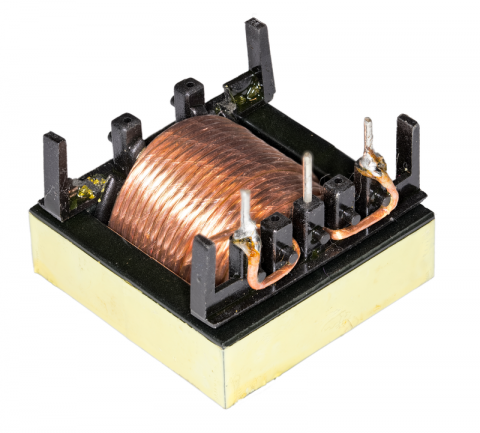

感应高频元件

功率因素校正的高频线圈

这个线圈是升压转换器的核心元件,根据转换器的拓扑结构,开关频率可达50KHz。

电流隔离高频变压器

变压器至少由初级和次级两个线圈组成。

电流隔离是通过将能量从电能转换到电磁能来实现的,因此电力可以通过空气间隙传输而无需机械连接。

出于安全考虑,电动车辆需要电流隔离,以便将电网电位与车辆电位分离。

将具有特定空气间隙和爬电距离的几种绝缘材料进行组合可以确保达到预定的击穿电压保护水平。

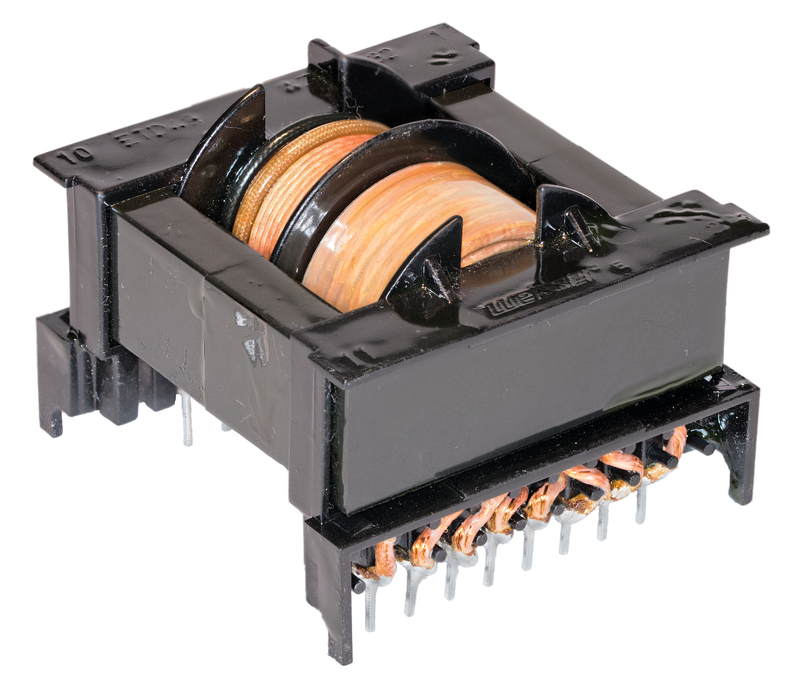

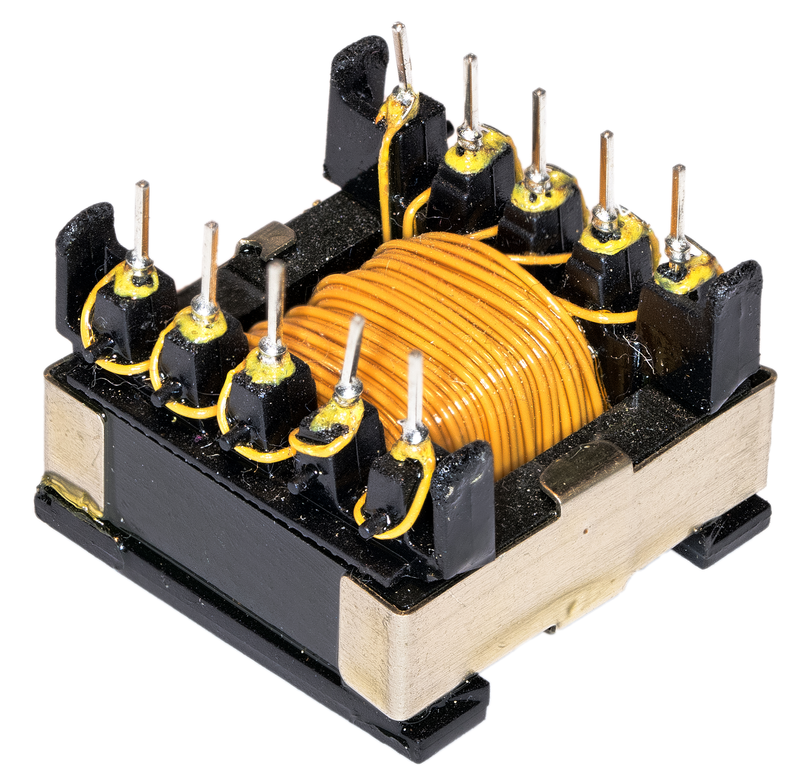

高频变压器设计示例:

针对高电压以及高安全要求的应用,益利素勒可提供VDE认证的EFOLIT 产品系列。

在以下产品链接中可以查看高频变压器可选用利兹线类型的概述:

- “EFOLIT利兹线”

- “膜包利兹线”

- “丝包利兹线”

- “定型利兹线”

1.1.2 DC/DC 转换器

概述

电动车至少有两种不同的电压系统,一种来自给所有汽车外围设备供电的低压蓄电池,另一种来自给驱动元件供电的高压动力电池。DC/DC转换器通过具备电流隔离的电压转换确保了在两个系统之间进行双向电能的传输。

DC/DC转换器的技术详解

电动汽车低压系统通常是基于电压水平在12伏到48伏之间的铅酸蓄电池。

电动汽车的高压系统则通常包括电压水平在200V到1000V之间的锂电池组。

DC/DC转换器的典型功率在1.5千瓦到5千瓦之间。

功率电子器件通常使用软开关拓扑结构与一个带电流隔离的谐振变压器级,两级之间通过升降压拓扑实现双向电能的传输。

感应高频元件

DC/DC转换器的效率是保证元器件最小结构体积和最小重量的关键。高开关频率有助于减小电感和变压器的尺寸。现代半导体技术使更高的频率成为可能,因而使得电感和变压器可以变得更小。

开关频率从100 kHz到550 kHz。高频利兹线产品经过优化,可以在保证高填充系数和高效率的同时保持高电压耐久性。

普遍使用的单线直径为0.05 - 0.1毫米。

典型的温度等级为B级(130°C)和F级(155°C) 。

利兹线材产品通常采用膜包、挤塑或丝包。

选择哪一种类型的利兹线取决于产品的应用参数,例如产品空间和对击穿电压的要求。

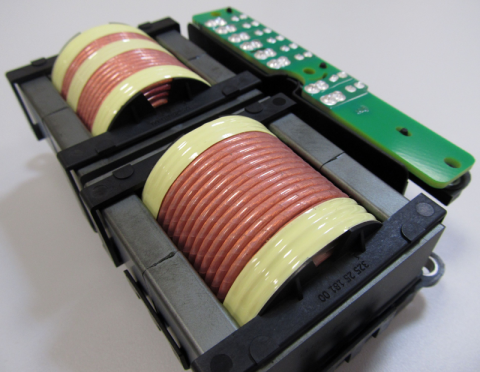

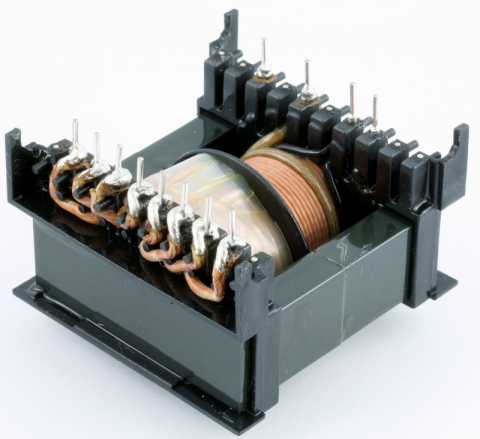

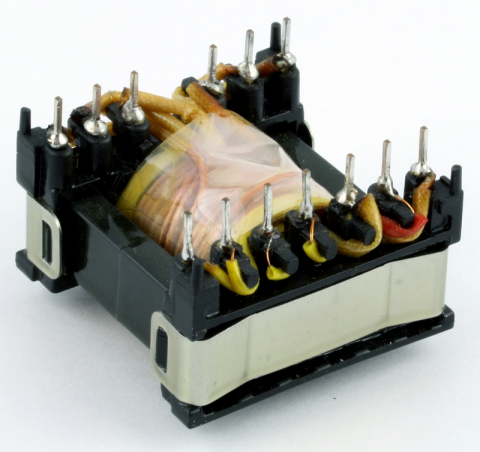

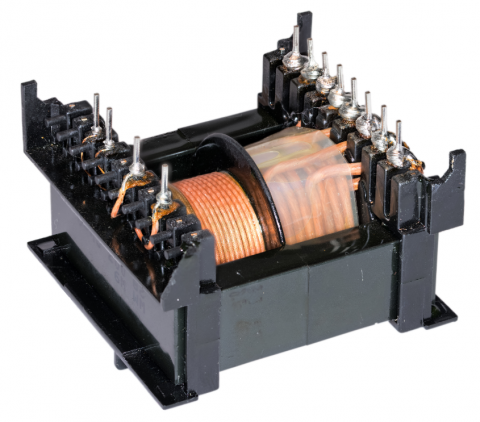

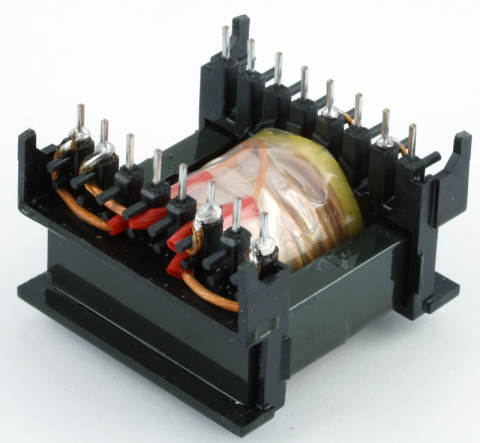

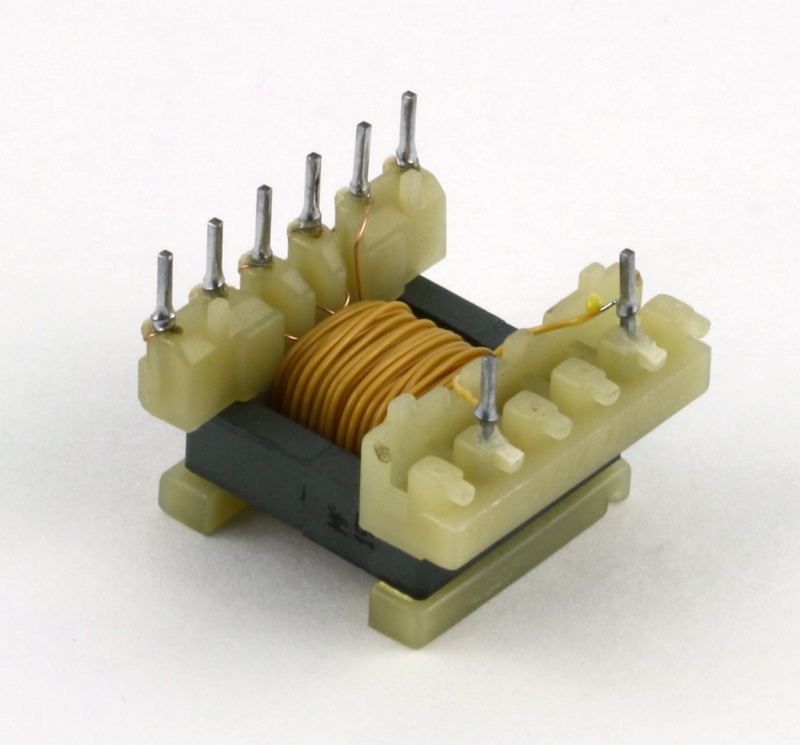

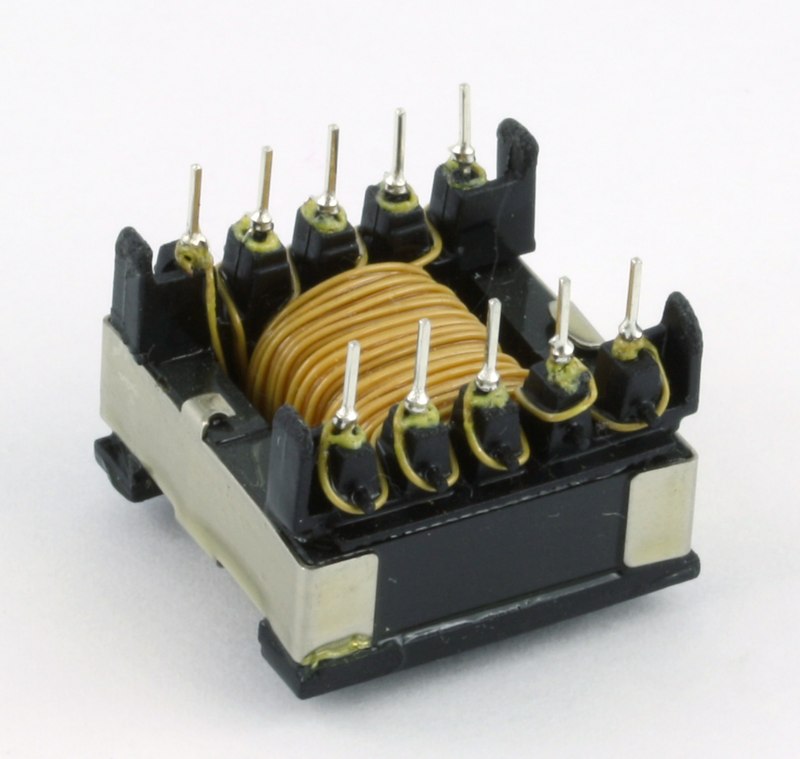

以下是高频变压器的一些例子:

1.1.3 无线充电

概述

无线充电(WC)或感应充电(IC)是无线电能传输(WPT)的方法中之一,电动汽车无线充电是一种非常方便的方式,因为电力可以通过较大的空气间隙传输,而无需任何电缆连接,传输效率很高。

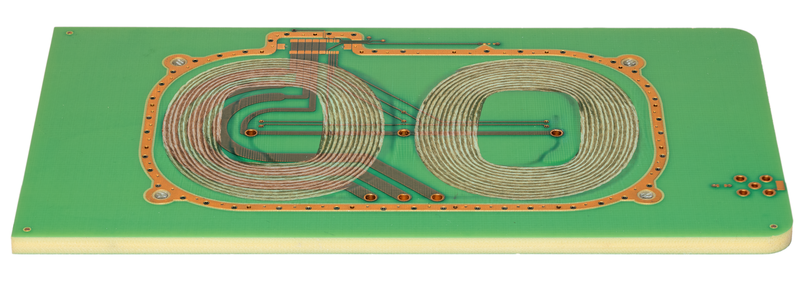

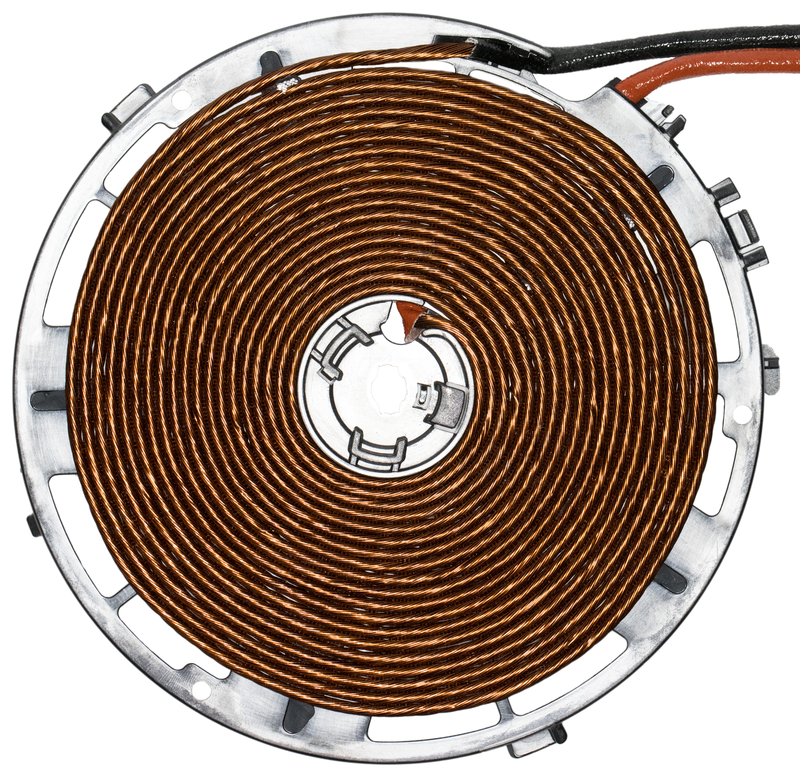

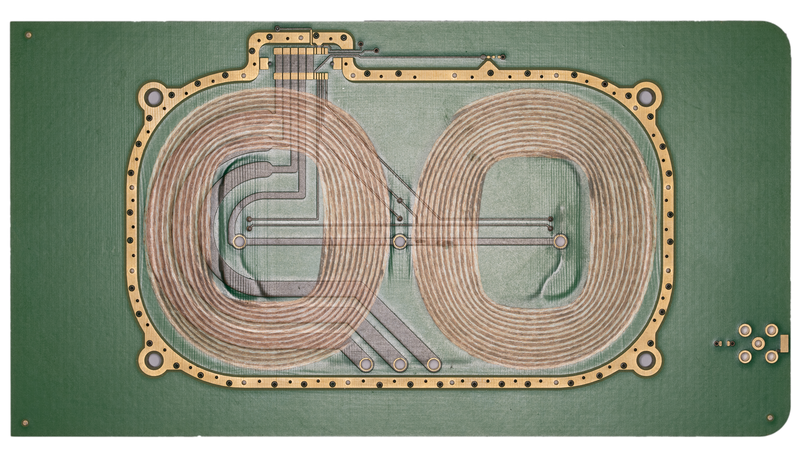

充电器使用两个平面感应线圈通过时变电磁场来传输能量。

无线充电有两种基本的不同类型::

静态无线充电

车辆在停车时充电,接收端线圈安装在汽车底部,发射端安装在地面上或地面下,充电过程中,接收端必须在停车时对准发射端。

动态无线充电

在这项未来的技术中,车辆可以在排列好的固定发射板上方边行驶边接收电能。

技术详解

有两种主要的感应式充电方式:

感应式无线充电(IWC),也叫感应式电能传输(IPT)

IWC的原理是“法拉第电磁感应定律”,在18世纪首次被应用,第一辆电动汽车就是在1970年使用IWC方式充电的。

S与前述车载充电机类似,充电机的第一部分是PFC级,用以确保正弦电流。电能的无线传输通过发射端和接收端线圈之间的磁场相互感应来实现。在初级线圈中,时变磁场是由交流电产生的,交流电在次级侧感应产生电压并使电子通过。随后电流流过次级线圈,交流电经过整流和滤波,为动力电池充电。

由于电压只有在磁场变化时才感应产生,因此需要一个快速变化的电流。感应式无线充电的典型工作频率在20至90千赫之间。感应式无线充电和变压器的工作方式类似,只是使用线圈代替金属磁芯。

磁共振式感应无线充电系统 (RIWC)

共振方式工作的线圈效率更高,因为阻抗会在谐振频率下减小。因此品质因数非常高。有关详细信息,请参见电磁基本原理。

此外,通过共振方式,能量可以传输到更远的距离。即使较弱的磁场也可以传输和感应式无线充电同样数量的电能。

为了将电能传输最大化,初级线圈和次级线圈的谐振频率应匹配。额外的补偿电路被添加到线圈中。这些电路进一步提高了效率。

磁共振式感应无线充电的典型工作频率在 10KHz 到 150 KHz。

无线充电标准

由美国汽车工程师学会制定的SAE J2954,定义了轻型插电式电动汽车的无线充电标准和定位方法。 更多细节请参见下表:

| 根据SAE J2854标准制定的无线充电功率等级 | ||

|---|---|---|

| 等级 | 功率 [kW] | 频段 [kHz] |

| WPT 1 | 3.7 | 81.39 - 90 |

| WPT 2 | 7.0 | 81.39 - 90 |

| WPT 3 | 11.0 | 81.39 - 90 |

在设计中,50千瓦的充电功率是常见的。对于重型车的应用,将多个50千瓦充电器组合在一起,每辆车可达到500千瓦。

此外,SAE J2954事先规定了线圈正确定位时的最低效率85%。

无线传输意味着必需要电流分离,其中发射端作为初级线圈,接收端作为次级线圈。

| SAE J2954标准定义的无线电能传输定位方法 | ||

|---|---|---|

| 等级 | 距离 [mm] | 频段 [kHz] |

| Z Class 1 | 100 - 150 | 81.39 - 90 |

| Z Class 2 | 140 - 210 | 81.39 - 90 |

| Z Class 3 | 170 - 250 | 81.39 - 90 |

使用利兹线的平面线圈的要求

- 单线

典型的利兹线结构使用直径在0.030mm和0.071mm之间的单线。

- 单线耐温等级

线圈温度不应超过100°C, 因此,低耐温等级的单线就可以满足要求。

- 利兹线绝缘

由于高压的要求,通常需要包膜。

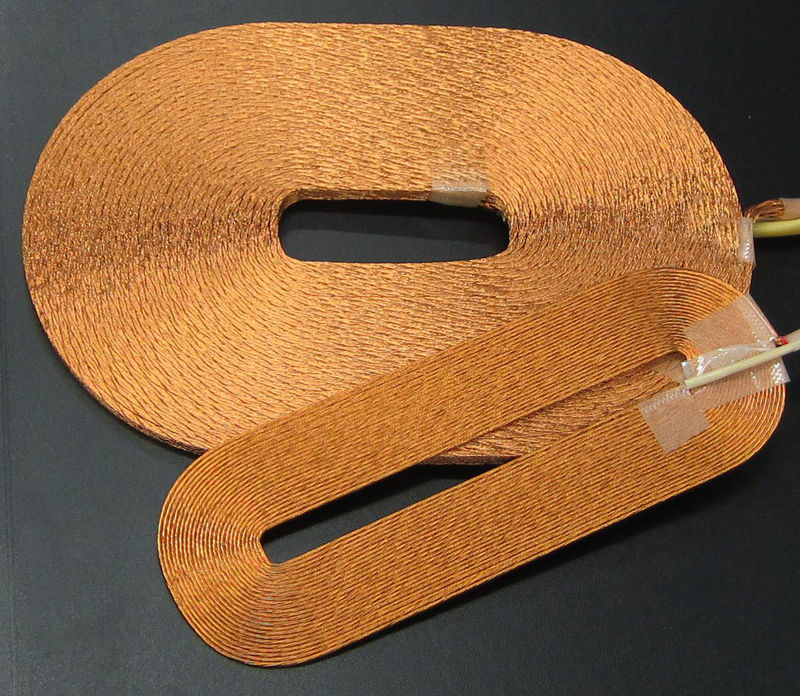

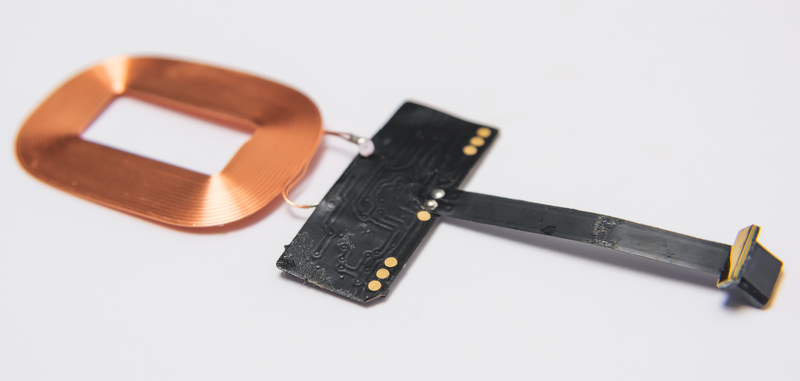

- 定型利兹线

为将磁场强度以均匀的密度分布,需要绕成平面线圈。

使用定型利兹线是一种在保持磁场均匀分布的同时保持高填充系数的常用方法。

1.1.4 充电桩 (AC/DC)

概述

充电桩为插电式电动汽车的动力电池充电过程提供电能。因此,有两种不同的充电桩可用于将电网中的交流电转换为电动汽车动力电池所需的直流电:

交流充电桩,为车载充电机提供能源。

直流充电桩,为电动车动力电池直接提供能源。这里的充电机是充电桩的一部分。

充电桩技术信息

交流充电桩

对于交流充电过程,充电机安装在电动汽车(车载充电机)上,详情见第1.1.1章。交流充电桩的特殊形式是无线充电器,详见第1.1.3章。

车载充电机可以通过公共充电桩或住宅充电桩站进行连接以获取电力.

公共充电

公共充电桩通常与公共停车场相结合。它们由商业公司或私人企业所有,有时与停车场所有者合伙经营。下表是不同充电桩的概述。

| 公共充电桩的交流充电类型 | |

|---|---|

| 插头类型 | 电压/功率r |

| Type 1 | 120V / 1.92kW or 240V / 3.8kW, 5.8kW, 7.2kW |

| Type 2 / Combo 2 | 400V / 3.6kW, 11kW, 22kW, 43kW |

住宅充电

住宅或私人充电桩,通常被称为“墙盒”充电器,是一种家用充电桩。电动汽车车主可以将其安装在私人设施中,以便在家中为车辆充电。但它们的输出功率通常因为没有较高电压的插座或电流限定,而受到限制。

下表中可以看到不同充电类型的对比 :

| 住宅墙盒交流充电类型 | |

|---|---|

| 插座类型 | 电压/功率 |

| 家用插座 | 120V / 1.4kW |

| 230V / 2.3W, 3.6kW | |

| 400V / 11kW, 22kW, 43kW | |

直流充电桩

不同于装在车上的车载充电机,直流充电桩没有内部空间和重量的限制,因此可以实现高于43千瓦的功率。

充电机集成在直流充电桩中,而外部充电机的电力电气原理与OBC是相同的。

直流充电桩通常采用模块化结构。因此,通过在充电桩中添加并联电路的模块,可以轻易地增加功率。

请参考下表中不同充电类型的对比 :

| 公共充电桩的直流充电类型 | |

|---|---|

| 插头类型 | 电压/功率 |

| CCS combo 1 | < 500V / <80kW |

| 类型 2 / 组合 2 | 200-1000V / < 350kW |

| CHAdeMO 类型 2 | 500V / <62.5kW |

| CHAdeMO 类型 2 | 1000V / < 400kW |

| 特斯拉超级充电站 | 480V / < 250kW |

充电桩用高频电感元件

对于未来的电动汽车,业界正开发基于800伏电压的上至450千瓦充电功率的技术。最先进的电力电子技术,使电压水平达到1000V成为可能。在这个高压水平,允许更快和更有效的充电。

这些发展趋势对充电机的电感器和变压器中的高频利兹线的绝缘能力提出了很高的要求。

与车载充电机相比,外部直流充电机可以提供更高的充电功率,因为其可用空间不受限制。车载充电的功率会受到部件重量和空间的限制。

直流充电机中高频变压器的典型利兹线结构使用直径为0.07-0.1 mm的单线,这对于在50和100 kHz之间的开关频率是最优的。

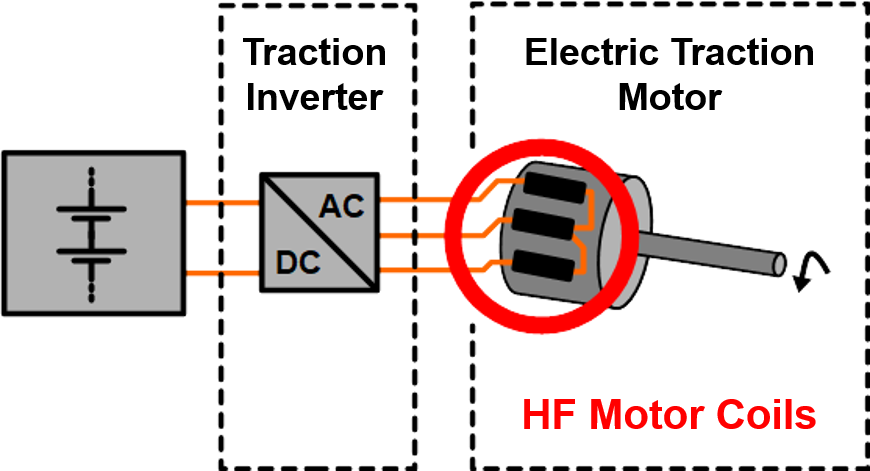

1.1.5 电机

概述

电机是电动汽车传动系统的核心,它的一大优点是从零转速到整个转速范围内都可获得高扭矩。

与内燃机(ICE)相比,电机已经具有很高的效率,但仍具有提升效率的潜力。电机由高功率逆变器驱动,开关频率上至50 kHz。用高频利兹线代替传统的单线结构可以降低线圈中的铜损。

对于电动汽车,必须根据汽车的要求选择电机,主要目标是提高功率密度,从而在电动汽车的整个生命周期内提高经济效率。

使用驱动电机的世界太阳能挑战赛赛车

电机技术信息

电机最基本的形式包括一个静止部件定子和一个以其为轴心的运动部件转子,这两部分都包含起磁通路径作用的磁钢片,两部分之间有一个很小的空气间隙,以保证旋转的能力。

定子磁钢片的外围有齿形结构(类似于齿轮),带有绝缘层的绕组在此绕制。

为了驱动电机,逆变器控制流经线圈的电流,从而形成从定子磁钢片经过空气间隙到转子磁钢片的磁通回路。通过这种方式,电磁力产生了扭矩,使电能转化为了旋转动能。

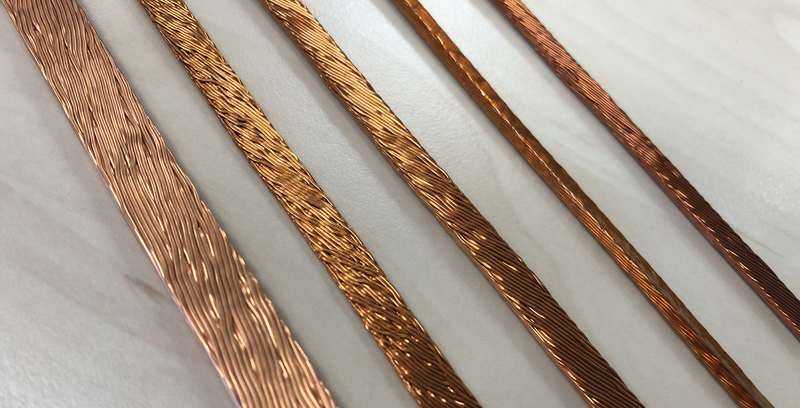

电机线圈元件

定子根据线圈和绕线过程的区别有两种主要的类型:

- 分布式绕组的定子,多个槽共用一个线圈

- 集中式绕组的定子,每个槽有自己的线圈

两种类型的定子具有不同的特性和不同的生产方法。

在传统工业电机中,绕组仅由一根漆包线绕成,这可以满足低功率电机的需求。对于更高功率的电动汽车,需要更大的铜截面。这可以通过平行线或铜条(称为发卡或ipin)来实现。这两种解决方案都有涡流损耗高的缺点。用利兹线代替可以在达到所需的铜截面积时,具有更高的填充系数,同时还可以补偿涡流损耗。

通过增加适当的股数以达到目标铜截面积,几乎可以使用高频利兹线设计每种功率水平的电机。

在从电能到旋转动能的转换过程中,会发生热量损耗。这些主要是铜损,分为直流损耗和交流损耗。

直流损耗可以通过增加铜截面积来降低。

交流损耗是由趋肤效应和邻近效应产生的涡流造成的。

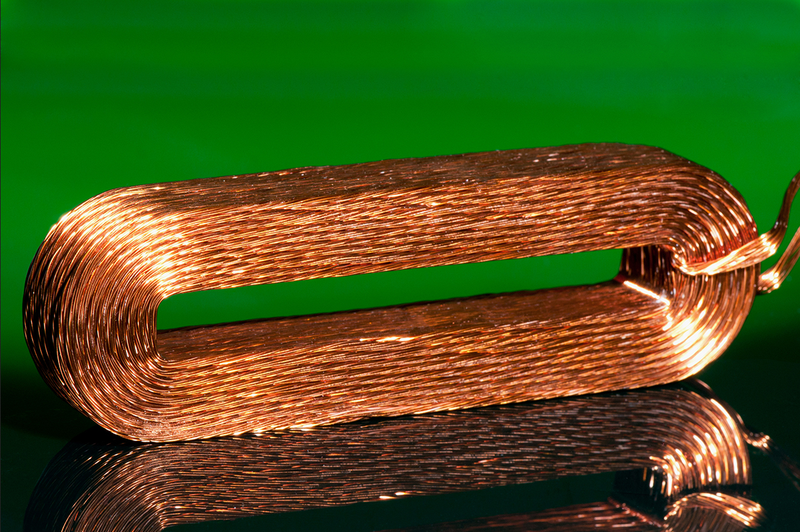

高频利兹线可以补偿涡流,从而提高电机的效率。

高频利兹线在电机中的另一个优点是提高了导热性,在改善散热的同时,也降低了高频损耗。

电动汽车驱动电机由于其高电压水平以及逆变器快速并接近矩形的开关模式,可能存在局部放电的高风险。可以用耐局部放电的高频利兹线进行设计,以确保长期的耐久性。我们可以提供膜包利兹线或者带有特殊绝缘漆的利兹线。

定型利兹线具有高填充系数和最佳槽利用率,对于分布式绕组它是一个很好的解决方案

集中式绕组也可以用自粘利兹线绕制的自我固定线圈来生产。利兹线首先被绕成一个线圈,然后压制,最后利用再软化的特性将线材粘合并固定在线圈上。

电机线圈通常需要做成矩形,以匹配电机的槽,实现高填充系数。利兹线可以被设计成具有很高的机械柔韧性,以实现较小的绕线半径,而不会像使用粗的单线一样损坏绝缘层。

电机中的频率必须区分逆变器开关频率和定子频率。主定子频率对涡流损耗的影响最大,根据转速通常可达到3 kHz。相应的高频利兹线就是根据这个频率设计的。

1.1.6 利兹线和电力电子器件的基本关系

开关频率和电感尺寸的关系

变压器、电感器和扼流线圈中的线圈尺寸可以通过使用更高的开关频率显著减小。

开关频率会受到开关过程中产生的热损耗的限制。因此开关时间必须缩短,以尽量减少电力电子器件的开关损耗,并减少线圈尺寸,以提高功率密度和缩小体积。

由于新型半导体材料的出现,功率晶体管技术的发展在开关速度和电压范围上都发生了重大变化。

根据下表,越短的开关时间意味着升压速度越来越快:

| 功率晶体管技术 | 升压速度 dU/dt | 电压范围 | 开始时间 |

|---|---|---|---|

| 双极晶体管半导体闸流管 GTO | <1kVµs | <300V | 1970 |

| IGBT | <10kV/µs | <1600V | 1990 |

| 碳化硅 氮化镓 | >35kV/µs | <1600V | 2010 |

高压趋势和利兹线绝缘材料的关系

电压越来越高的趋势对利兹线的绝缘材料提出了更高的要求。此外,变压器匝间的高电势差,需要匝间始终保持高度绝缘。

这是由高频开关电压引起的,特别是在带有谐振电路的转换器拓扑结构中。

益利素勒为每种电力变压器单独设计利兹线,以实现最高的效率、高电压保护、热导率和填充系数。

开关模式,击穿电压和局部放电的关系

在所有电力电子器件中,半导体开关通过控制电压使电流输入电感器。在高频应用中主要是由利兹线组成。根据硬开关和软开关的应用,开关方法有所不同。

硬开关是指开关操作时电流和电压不等于零。因此开关损耗高,耐久性差。由于电感上的电压随时间增加很快,因此局部放电的风险很高。

软开关是指在开关操作时电流和电压为零。晶体管内部的开关损耗很低,提高了电力电子器件和电感元件的效率和耐用性。局部放电的风险很低。

1.2 座舱加热

概述

益利素勒率先为汽车座椅加热应用开发了使用漆包单线的利兹线,以避免座椅出现局部高温点。后来又引进了不同的合金和外层挤塑对利兹线进行了进一步的改进。

随着加热座椅,加热方向盘变得越来越流行。原本用于高端车的座舱电加热系统现在已成为许多级别车辆的标准配置。

传统的内燃机汽车利用发动机的余热来加热车厢。

这在电动汽车中是不可行的。因此,需要低能耗的高效加热方式,例如。

- 加热直接接触的表面,如座椅、扶手或方向盘,以及

- 乘客附近面板的辐射加热可以作为一种有效的设计选项。

对于许多加热应用,漆包利兹线已成为应对技术,机械和电气的挑战的最先进的解决方案。

单独设计的利兹线允许设计者实现精确的温度分布,同时也避免了因过大的弯折力或不当操作造成利兹线内部断股而导致的局部高温点。

技术详解

加热应用中漆包利兹线最重要的技术要求:

- 无局部高温点

如上述说明

- 弯折寿命性能

由于座椅在日常使用中通常会受到强烈的机械冲击,因此加热线在其使用期内必须能够持久地抵抗弯曲和拉伸引起的机械应力。侧面的靠垫是机械要求尤其高的区域。优化的线材直径、合金的选用、特殊的绞合方式设计和可选的挤塑护套是显著提高弯折寿命的主要影响因素。当有需要时,在非常小和细的利兹线结构中加入应力消除元件也会有帮助。

- 加热电阻

使用高抗张强度但柔韧性较差的合金材料可能会导致绞合的利兹线线产生更多的卷曲,从而导致纠缠或打结。这可能会导致缝纫过程中损坏线材。特殊的绞合设计、最佳的线材处理和绞合方式可将这种影响降低到最低。可选的外层挤塑对卷曲表现有积极影响。

- 卷曲表现

导体截面积和合金的优化组合最终确保了加热区域内精确的电阻和温度分布。特定的利兹线电阻(单位:欧姆/米)和电阻温度系数决定了加热导体所有长度的最终加热性能。

在高温和机械应力作用下,漆包线的绝缘层会产生针孔。这些是漆层的微观裂纹。通过选择合适的绝缘漆类型、生产过程中妥善处理线材和优化绞合方式,可以避免针孔。

汗液、软饮料、牛奶、咖啡、清洁剂及其它液体会影响加热丝的使用寿命。通过扩散,绝缘层会受到腐蚀影响,并导致加热元件的过早失效。恰当的绝缘漆类型、漆膜厚度等级和可选挤塑层的组合可以提高耐化学性,并保护加热丝免受此类影响

- 针孔

- 耐化学性

1.3 座舱电子

概述

手机无线充电是一个越来越常见的座舱配置,因为客户可以不再需要充电线。

在市场上,无线充电系统有两种技术被广泛应用:

感应式无线充电系统

电能的无线传输是通过发射端和接收端线圈之间的磁场相互感应来实现的。在发送端线圈中,交流电产生一个时变磁场,并向各个方向发射。在这个系统中当一个与发射线圈尺寸相同的接收线圈被精确地放置在发射线圈上方几毫米的位置时,可以获得最高的电能传输效率。

感应式无线充电系统的主要优点是,当发射端和接收端紧密耦合时,效率相对较高。

当需要高效率的充电系统时,首选这种系统。

磁共振式无线充电系统

这个系统仍然是“感应式的”,即发射线圈产生的磁场在接收线圈中感应产生电流。然而,传输能量是在比感应系统更高的频率下完成的,并且需要发射端和接收端线圈在相同谐振频率下工作。在磁共振式无线充电系统中,线圈之间形成了一种能量通道,允许在更大距离、多个线圈之间和多个方向上进行能量传输。

由于漏磁,即使在紧密靠近的线圈中,系统也会有一些效率损失。

因此,当需要方便灵活地放置接收端时,首选该系统。

技术标准

消费类电子产品的无线充电有两个主要标准:

- Qi

(由无线充电联盟“WPC”开发)

技术: 感应和磁共振

工作频率: 85 kHz - 205 kHz

发射端功率水平:5W – 15W

- 磁共振

(由无线电力联盟“A4WP”开发)

技术:磁共振

工作频率: 6.78 MHz

PTU(电能发射单元)功率水平:2 W - 70 W

PRU(电能接收单元)功率水平:3.8 W - 50 W

Qi标准中的无线充电器元件

Qi标准中规定了发射端从A1到A34(具有一个或多个初级线圈)以及从B1到B7(具有一个阵列的初级线圈)的设计类型。不同的设计类型在线圈尺寸和形状(圆形、椭圆形和方形)等方面各不相同。各种类型均使用单线为0.08 mm的不同股数(从24到180)的利兹线。

尽管Qi标准没有定义电能接收端,但它用与发射端类似的利兹线结构作了一些举例。

典型的利兹线产品

用于无线充电设计的典型利兹线产品,请参见以下链接:

- “自粘线”

- “普通利兹线”

- “丝包利兹线”

- “睿智绞线”

2. 工业电子

2.1 开关电源

概述

开关电源(SMPS)为电气和电子设备提供特定的低压直流电(DC)。因为开关电源具有效率高、结构紧凑、重量轻、输入电压范围宽等优点,在工业上有着广泛的应用。

例如:

- 充电系统

- 实验室和测试设备

- 焊接技术

- 医疗和信息技术系统

技术详解

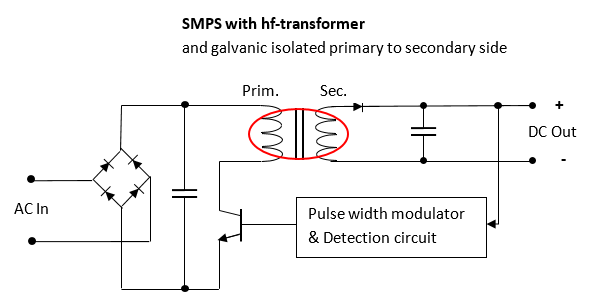

来自公共交流电网的电能,通过快速开关半导体拓扑结构转换为高频(HF)电源,见图1。为了将高频输入电压转换为较低的交流电压,需要一个高频变压器。其尺寸可以通过增加工作频率(30kHz-500kHz)来缩小。

通常,高频变压器采用分层绕组和数量较少的匝数。为了有效地降低高频损耗,高频利兹线的使用是必要的。出于安全原因,变压器的初级(输入)侧必须与次级(输出)侧分开。

典型的利兹线产品

可以使用隔离挡墙和凸缘等绝缘结构元件,以保证电气间隙和爬电距离。

一种更紧凑和节省空间的技术方案是使用加强绝缘绕组线(FIW)。在这种情况下,可以减少空气间隙和爬电距离,实现具有更高功率密度的更小和更轻的设计。

为满足对更高工作频率和更紧凑变压器尺寸日益增加的要求,益利素勒提供了以下设计选项:

- 天然丝或尼龙丝包利兹线保证了良好的柔韧性和形状稳定性,以实现最佳的绕线性能。

- 带附加绝缘膜的高频利兹线可提供高达10 kV的击穿电压。

- 益利素勒的加强绝缘和VDE认证的EFOLIT® 产品系列可满足开关电源设计中非常高的安全要求。

- 矩形或方形的定型(压制)利兹线确保了利兹线和线圈绕组的最佳铜填充系数。

2.2 传感器

概述

漆包利兹线优化的高频(HF)性能和针对独特设计的众多产品可能性使利兹线成为传感器和天线的理想材料。

例如

- 感应式接近传感器

- 金属探测传感器

- 无线射频识别系统线圈

- 近场通信线圈

技术详解

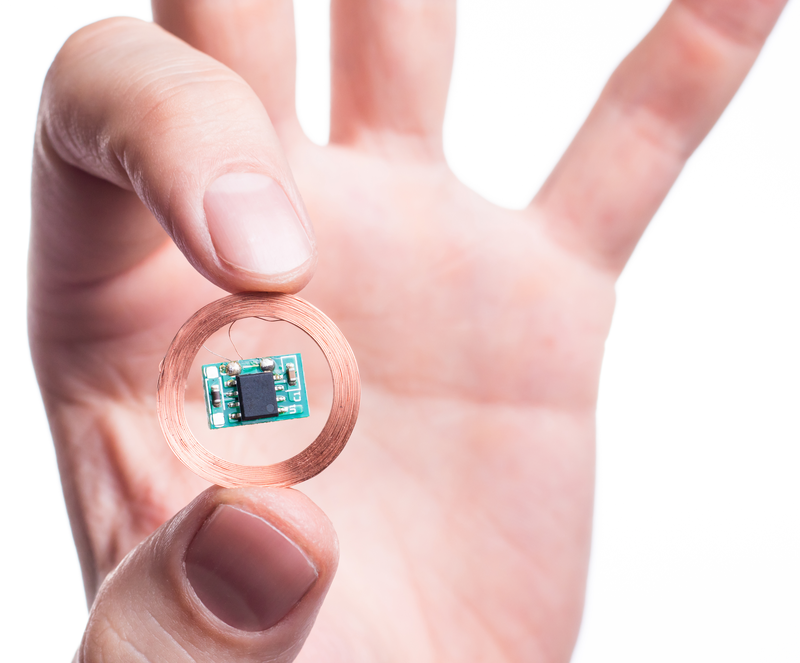

无线射频识别 (RFID)

读取设备产生一个高频磁场( 例如门形)作用于应答器天线。在天线中感应产生电压;芯片被激活,并通过场衰减产生单独的响应。读取器接收响应。

近场通信 (NFC)

NFC为两个电子设备之间4厘米距离内的通信定义了不同的通信协议。

以下应用范例可使用低速连接:

- 非接触支付系统

- 信息交换

- 身份证和访问令牌

- 智能手机自动化

- NFC标签

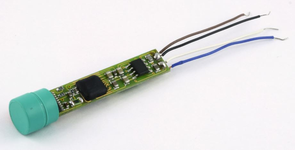

感应式接近开关

传感器的功能是通过一个由线圈和电容组成的振荡电路来实现的,其表征是Q值。线圈本身会产生一个覆盖探测区域的电磁场。在该区域中出现导电元件时,由于涡流损耗,Q值会改变。

通过接近开关的电路检测来磁场能量损失,并感应到元件。

RFID设备和接近开关可用于物流、过程自动化和铁路技术。

天线(或磁场发生线圈)通常没有线圈骨架或载体元件。在这些基于自粘技术的空心线圈中,使用丝包或挤塑的利兹线。

典型的利兹线产品

益利素勒提供以下设计选项:

- 使用自粘漆包线的高频利兹线可获得最小弯曲半径并具有较高的铜导体填充系数。

- 带有Smartbond自粘层的各种利兹线可以确保简便的热风自粘并具有非常高的铜导体填充系数。

- 益利素勒的热粘合天然丝或尼龙丝包线可以保证最佳形状稳定性和空心线圈的可绕性。

3. 医疗电子

3.1 助听器 (连接线)

概述

助听器的目标是尽可能小和尽可能的轻,以提高用户的舒适度,并尽量减少可见度。传统的连接电缆通常已由更轻的利兹线代替,因为单线是绝缘的并可以用作电缆。

般要求

- 镀银保护以避免环境影响

- 表面镀银层颜色光亮

- 一致的焊锡性能

- 极好的弯折性能

- 使用加强纤维后牢固度高

- 挤塑表面非常光滑

- 直径公差(圆度和尺寸)要求极高

- 完美的去皮性能易于电气连接

3.2 其他应用

4. 家用电器

4.1 感应烹饪

概述

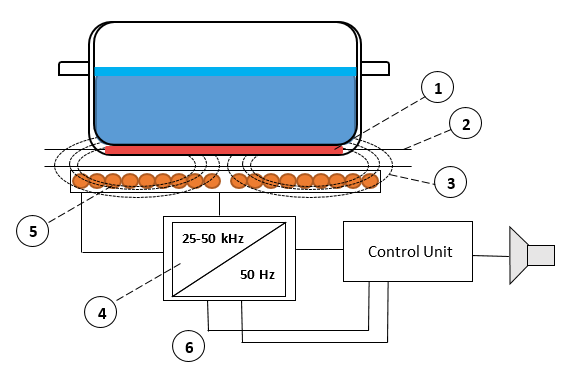

在锅或盘的底部感应产生一个交变磁场,并通过涡流损耗转化为热能。发射线圈的热损耗非常小,因此可以缩短加热时间,烹饪时炉盘表面仍旧可以保持低温。

技术详解

工作频率: 20 kHz - 60 kHz

- 铁质材料制成的烹饪锅底

- 玻璃陶瓷(炉盘表面)

- 交变电磁场

- 逆变器

- 感应利兹线圈

- 电网

感应烹饪组件

感应导体要求

- 高耐温等级

- 高击穿电压

- 高机械强度

- 高填充系数(压缩绕组)

感应式炉盘的典型利兹线

- 高频平面线圈使用普通利兹线

- 导体材料:铜、铝或者铜包铝

- 单线线径范围:0.18-0.4mm

- 股数: 20-120股(取决于炉盘的大小和工作频率)

- 高耐温无气味的绝缘漆(≥ 200 °C)

- 可选择定型:用于提高填充系数(定型利兹线)

5. 再生能源

5.1 太阳能逆变器

概述

太阳能逆变器是太阳能发电系统的核心,它将太阳能板上的直流电转换成电网的交流电。

同时逆变器中的电子控制器对整个太阳能发电系统和电网进行监控。

太阳能逆变器的功能如下:

- 从低压直流电到高压交流电的高效能量转换

- 功率最大化

- 监控功率和温度数据

- 智能能源系统的通信

- 对温度进行管理避免太阳能板温度过高

太阳能逆变器的技术详解

太阳能逆变器可以根据以下3个属性来分类::

- 功率

功率范围从数千瓦到兆瓦级别。个人住宅的典型功率值为5千瓦,工业用为10- 20千瓦,太阳能发电厂为500 千瓦及以上。

- 互连模块

在直流端,太阳能逆变器可以连接一串,多串,或中心拓扑结构,这取决于功率和能效的要求。

- 拓扑电路

逆变器可以被设计成适用于单相交流电网或三相交流电网,可以带电流隔离或者不带电流隔离。

电流隔离是通过直流和交流侧之间的变压器实现的。隔离的模块可以接地,以防止交流电位差,这也是一些国家的强制性规定。

无电流隔离的逆变器直流侧和交流侧电相连,可以有更高的效率的优势,但缺点是对地有交流电位差,限制了其寿命。

Litz Wire Requirements for Solar Inverters

- Temperature index TI = 155 °C

- High mechanical robustness

- Good flexibility

- High dielectric breakdown voltage

6. 消费电子

6.1 开关电源变压器

概述

开关电源变压器(SMPS)为电气和电子设备提供特定的低压直流电(DC),高频变压器是实现降低电压的关键元件。

开关式电源变压器由于其高效、紧凑和轻便的设计,以及可变输入电压,不仅在工业电子应用中,而且在消费电子领域得到了广泛的应用。

例如:

- 智能手机充电器

- 笔记本电脑充电器

- 个人电脑

- 多媒体系统

- 电视机

- 家用电器

- 充电系统

技术详解

通常一个消费电子设备有两个位置安装开关电源变压器单元:

外部(电源电缆)

内部(电子设备和电感元件直接安装在主板上)

SMPS的高频变压器如下图:

更多的技术细节和利兹线产品信息请参考开关电源在工业电子中的应用(参见2.1)。

6.2 智能织物

利兹线被用于智能织物的一些特殊应用中。通常使用非常细的利兹线,因为利兹线必须混入织物,而不破坏其基本的纹理。同时,日常使用中粗糙的处置,以及清洗或清洁,都对线材提出了非常苛刻的要求。

概述

- 运动和休闲服

- 安全部队的防护装备,无线射频识别系统

- 大厦安防技术

- 节日装以及制服

- 机械工

技术详解

- 利兹线的完成外径很小

- 具备织物特性,精细的结构

- 高抗张强度,可以拼接,良好的弯折寿命特性

- 具备化学稳定性

不易褪色

在织物应用中需要使用特殊的漆包线,参见

智能织物线材的基本特性

- 单线直径范围:0.02mm-0.071mm

- 单线股数:2-100股

- 导体材料:镀银或者不镀银的铜及合金

- 绝缘:聚氨酯类绝缘漆、低熔点的挤塑层

- 可选:单线为裸线

- 可选:应力消除

- 可选:包覆尼龙丝或者天然丝作为机械保护

6.3 无线充电

概述

市场上的无线充电器有无线充电板、家具内置无线充电器,或带有无线充电器的USB底座等。这种充电器需要在用户的智能手机,手表等电子产品中有一个接收器。

无线充电器为消费类电子产品提供以下优点:

- 不需要连接线

- 不需要专门的连接器

- 节省了充电端口

在市场上,有两种无线充电系统的技术被广泛应用:

感应式无线充电系统

电能的无线传输是通过发射端和接收端线圈之间的磁场相互感应来实现的。在发射线圈中,交流电产生一个随时间变化的磁场并向各个方向辐射。在这个系统中当一个与发射线圈尺寸相同的接收线圈被精确地放置在发射线圈上方几毫米的位置时,可以获得最高的电能传输效率。

感应式无线充电系统的主要优点是当发射器和接收器紧密耦合时,效率相对较高。

当需要高效率的充电系统时,首选这种系统。

磁共振式无线充电系统

这个系统仍然是“感应式的”,即发射线圈产生的磁场在接收线圈中感应产生电流。然而,传输能量是在比感应系统更高的频率下完成的,并且需要发射端和接收端线圈在相同谐振频率下工作。在磁共振式无线充电系统中,线圈之间形成了一种能量通道,允许在更大距离、多个线圈之间和多个方向上进行能量传输。

由于漏磁,即使在位置较近的线圈上,系统也会有一些效率损失。

因此,当需要方便灵活地放置接收端时,首选该系统。

技术标准

消费类电子产品的无线充电有两个主要标准:

- QI(由无线充电联盟“WPC” 开发)

- 技术:感应和磁共振

- 工作频率:85 kHz - 205 kHz

- 发射端功率水平:5W-15W

- Rezence(由无线电力联盟“A4WP” 开发)

- 技术:磁共振

- 工作频率:6.78 MHz

- PTU( 电能发射单元) 功率水平: 2W-70W

- PRU(电能接收单元)功率水平: 3.8W-50W

Qi标准中的无线充电器元件

Qi标准中规定了发射端从A1到A34(具有一个或多个初级线圈)以及从B1到B7(具有一个阵列的初级线圈)的设计类型。不同的设计类型在线圈尺寸和形状(圆形、椭圆形和方形)等方面各不相同。各种类型均使用单线为0.08 mm的不同股数(从24到180)的利兹线。

尽管Qi标准没有定义电能接收端,但它用与发射端类似的利兹线结构作了一些举例。

典型的利兹线产品

用于无线充电设计的典型利兹线产品,请参见以下链接:

- “自粘线”

- “普通利兹线”

- “丝包利兹线”

- “睿智绞线”

7. 特殊线缆

概述

因为每一根单股漆包线都具有很强的绝缘能力,可以用和电缆类似的方式来使用利兹线。挤塑利兹线可以用于进一步加强机械和电气性能,但同时增加了重量和体积。在一些应用中,漆包利兹线被直接作为电缆使用,这在直径、重量和体积上都有优势。使用有颜色的单线有助于在后续加工过程中区分利兹线中的各股。

典型的利兹线

以下是一些特殊利兹线导体和线缆的例子

- 具有超细和非常复杂绞合结构的高频利兹线,例如600 x 0.010毫米或25.000 x 0.20毫米。

- 最小完成外径仅为毫米级的微型电缆,例如7 × 0.010毫米。

- 使用热粘合自粘漆包线的诊断电缆。例如双绞线(2 x 0.020毫米)或平行多股线。

- 具有最大的柔韧性以及低摩擦结构和绝缘漆涂层随行电缆。

- 导体使用特殊合金的耐振信号线(如7 × 0.04毫米)。

- 用于耳机线缆的利兹线,通过挤塑使线缆细而轻。

- 具有特殊颜色编码的高频利兹线。

服务

益利素勒是您的高频利兹线合作伙伴

成为客户的合作伙伴并为其提供量身定制的服务是我们的目标。从利兹线的最初设计到最终产品的快速发货,我们始终确保我们的客户能得到最优质的服务。

应用技术咨询

益利素勒的理念是成为客户的合作伙伴而不仅仅是供应商。因此,我们关注的重点是利兹线的研发和技术支持。客户可以利用我们在全球的资源获得利兹线的客户支持和技术应用服务,为其特殊应用开发出创新和高性价比的解决方案。

利兹线的操作

利兹线的处置不当容易对线材和线轴造成损坏,引起出线问题。

典型的损伤有:

1. 对线轴或线轴凸缘的机械撞击。这种剧烈碰撞往往会在塑料轴上留下白色的印记,并会导致排线错乱或导致上层的线下滑。线轴凸缘的机械损伤也会因粗糙或锐边而导致在出线过程中线材断线。

2. 线材包装受到震动。线轴或纸箱的跌落,会使排线因剧烈震动而移位,错乱的排线会造成使用时的出线困难。

3. 排线下滑,可能因上述1和2的不当操作造成,排线会下滑并互相重叠,造成线材打结甚至断线。

排线下滑

4. 排线损坏。经常是因为在处置或搬运单个线轴时与其它线轴发生碰撞,或者从纸箱中取出时线轴不垂直而刮到纸箱的边缘。这会导致出线问题并破坏利兹线结构。

样品

选用最佳的利兹线设计结构可以对最终产品的整体成本和性能都产生正面的影响。益利素勒具备定制利兹线结构和快速生产样品的能力。只要跟我们联系,我们很乐意为您提供所需的样品。

物流

先进的生产技术、雄厚的制造实力、极高的效率、便捷的沟通渠道以及在微细漆包线操作、包装和运输方面长期的经验使益利素勒成为值得信赖的合作伙伴,可以为客户提供快速的交货和可靠的运输。

库存规格

库存清单包含用于测试和简单模拟的样品数量。它仅代表经过挑选的一小部分利兹线材产品。因此,合格的量产产品可能会有差别!如需提供个性化的解决方案和定制的利兹线设计请与我们联系。