Enamelled Wire

El alambre esmaltado es un conductor metálico aislado con un barniz y generalmente usado en aplicaciones eléctricas. La mayoría de la veces se enrolla de diferentes formas de bobinas para generar una fuerza magnética en motores, transformadores, imanes, etc. Elektrisola produce mas de 30,000 tipos diferentes de alambre esmaltado con las características más importantes, tales como:

Material Conductor

Copper is the standard used conductor material for enamelled wire with excellent conductivity and very good windability. For low weight and larger diameters, Aluminium sometimes can be used as a conductor material for enamelled wire. Because of the difficult contacting of Aluminium wire with problems of oxidation, Copper Clad Aluminium can help to compromise between Copper and Aluminium. For special applications a wide variety of conductor materials for enamelled wire is offered, such as Brass, Silver, Nickel, Gold, Stainless Steel, or alloys of copper for special characteristics like higher mechanical strength or bending performance. In addition, the core conductors can be plated with different materials such as Silver or Nickel.

Rango de Diámetro del Alambre Desnudo

Elektrisola se especializa en alambres finos, empezando con 0.008 mm (8 micras), y llegando hasta un diámetro de 0.50 mm. Además de los diámetros estandarizados, se producen un gran número de diámetros especiales de acuerdo a las especificciones del cliente. Las tolerancias del alambre desnudo son muy importante, ya que tienen un impacto directo en la resistencia, lo que determina nuevamente la variación de la resistencia final de la bobina.

Diámetro Exterior

International standards like IEC group enamelled wires according to ranges of specific outer diameters. IEC standard for enamelled wire groups the insulation in Grade 1, 2, or 3, NEMA in single, heavy, or triple, and JIS in class 0, 1, 2, or 3. The tolerances in these enamelled wire standards can be further restricted if necessary to design and optimize the wound coils and final products.

Capa Autoadherible

Además de las capas base de aislamientos descritos anteriormente, se puede aplicar unas capa autoadherible, mediante la cual el alambre se unirá enre sí, por ejemplo, las bobinas auto-soportadas, como las bobinas de voz.

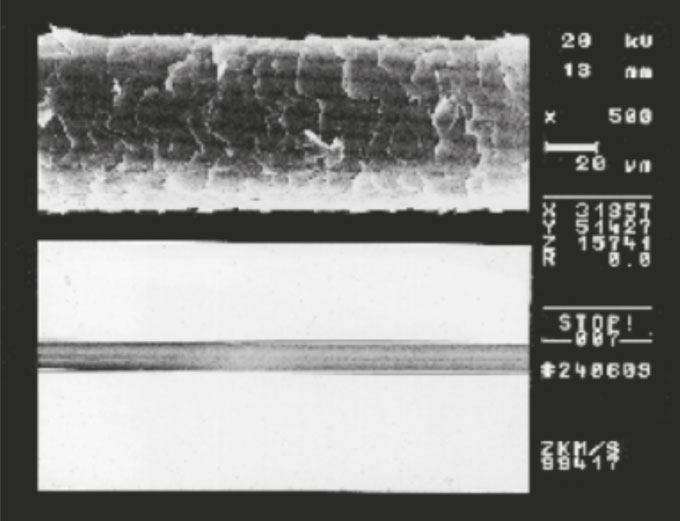

Foto de luz trasnmitida de un alambre autoadherible de 0.09 mm AB15 verde

V=200 X

Tipos de Carretes

Los tipos de carretes de deben de ajustar al tamaño del alambre. Los alambres mas finos se enrollan en carretes más pequeños, mientras que para los alambres más gruesos se pueden usar carretes mas grandes. Los carretes son importantes para la productividad, ya que carretes más grandes requieren menos cambios de carretes en las máquinas bobinadoras.

La longitud del alambre en un carrete puede ser muy grande:

0.018 mm en carrete 99L: hasta 417 km

0.05 mm en carrete 199L: hasta 1143 km

0.30 mm en carrete 400/630: hasta 277 km

Tipos de Aislamiento

Elektrisola ofrece una amplia gama de diferentes aislamientos. Poliuretano tiene la ventaja de un fácil contacto directo mediante soldadura, mientras que el aislamiento de Poliester es mas resistente a temperaturas altas. Pequeñas capas en la superficie, como Nilon o Poliamidaimide pueden mejorar ciertas caracteristicas deseadas, como la resistencia mecánica o química.

Colores

Los colors pueden ser usados para diferenciar los tipos de alambre o diámetros, pero tiene la desventaja de disminuir las propiedades técnicas y altos costos.

Lubricante

Se aplica una cantidad muy baja de lubricante –en su mayoría algunos tipo de parafina– para lograr una excelente capacidad de embobinado del alambre durante el proceso de embobinado evitando las rupturas de alambre.

Elektrisola se especializa en diámetros finos y ofrece una amplia varidad de productos que van de 0.008 mm (8 micras) a 0.50 mm con diferentes tipos de esmaltes en diferentes tipos de materiales conductores.

Diámetros

Para cobre: 0.008 mm – 0.50 mm

Para otros materiales: favor de preguntar

Especificaciones

Elektrisola produce alambres esmaltados de acuerdo a muchas diferentes especificaciones. La especificacion más importante a nivel mundial es IEC, además de NEMA en Norte America y JIS en Asia.

Tipos de Esmaltes

Poliuretano

es un barniz de fácil contacto directo mediante soldadura o prensado. Especialmente para alambre fino, la fácil soldadura es la mayor ventaja de este tipo de esmalte. Los poliuretanos están disponibles con un índice de temperatura de 155° C (Polysol © 155) y un índice de temperatura de 180° C (Polysol © 180). Este esmalte está disponible de 0,008 a 0,50 mm en todos nuestros materiales conductores.

Poliesterimidas

are more resistant against higher temperatures and beside the pure Polyesterimide (Estersol© 180) not usable for direct soldering of enamelled wire. Under this enamel type also Theic-modified Polyesterimide (Amidester© 200) or (Amidester© 210) are listed.

Polyamidimides and Polyimides

have the highest temperature and chemical resistance and you will find them as I220-enamelled wire or ML240©-enamelled wire at ELEKTRISOLA product portfolio.

Based on the above mentioned enamel types, you can combine all these enamels with a self bonding coat such as Polyvinylbutyral, Polyamide or Polyester.

Selfbonding wire can be bonded by different methods

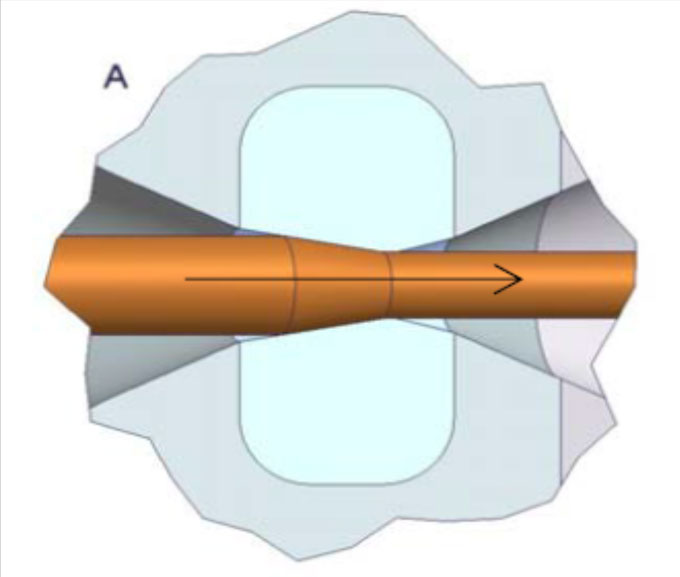

Proceso de Trefilado

Para los alambres de cobre, se utiliza una varilla de cobre de 8 mm (5/16 ″ en EE. UU.) como materia prima, que, mediante dados de trefilado, se estira al tamaño de alambre desnudo requerido en varias etapas. La varilla de cobre debe ser de alta pureza y consistentemente de alta calidad para fabricar alambres finos y ultrafinos de tamaños inferiores a 10 µm. ELEKTRISOLA utiliza solo cobre electrolítico puro ETP1 (contenido de cobre mínimo 99,99%) de proveedores de alta calidad previamente aprobados.

El proceso de trefilado se lleva a cabo secuencialmente a través de varios grupos de máquinas que producen rangos de diámetro específicos. El alambre se elonga en varias etapas a través de dados, de modo que el alambre más grueso se vuelve permanentemente más delgado y más largo durante el proceso de trefilado mientras el volumen permanece sin cambios.

La calidad del cobre, el ajuste fino entre las diferentes etapas de trefilado y especialmente la calidad de los dados de trefilado son de gran importancia para lograr un alambre desnudo final de alta calidad. La superficie por donde pasa el alambre en los dados de trefilado consiste en diamante natural, artificial o, para la producción de alambre grueso, de carburo.

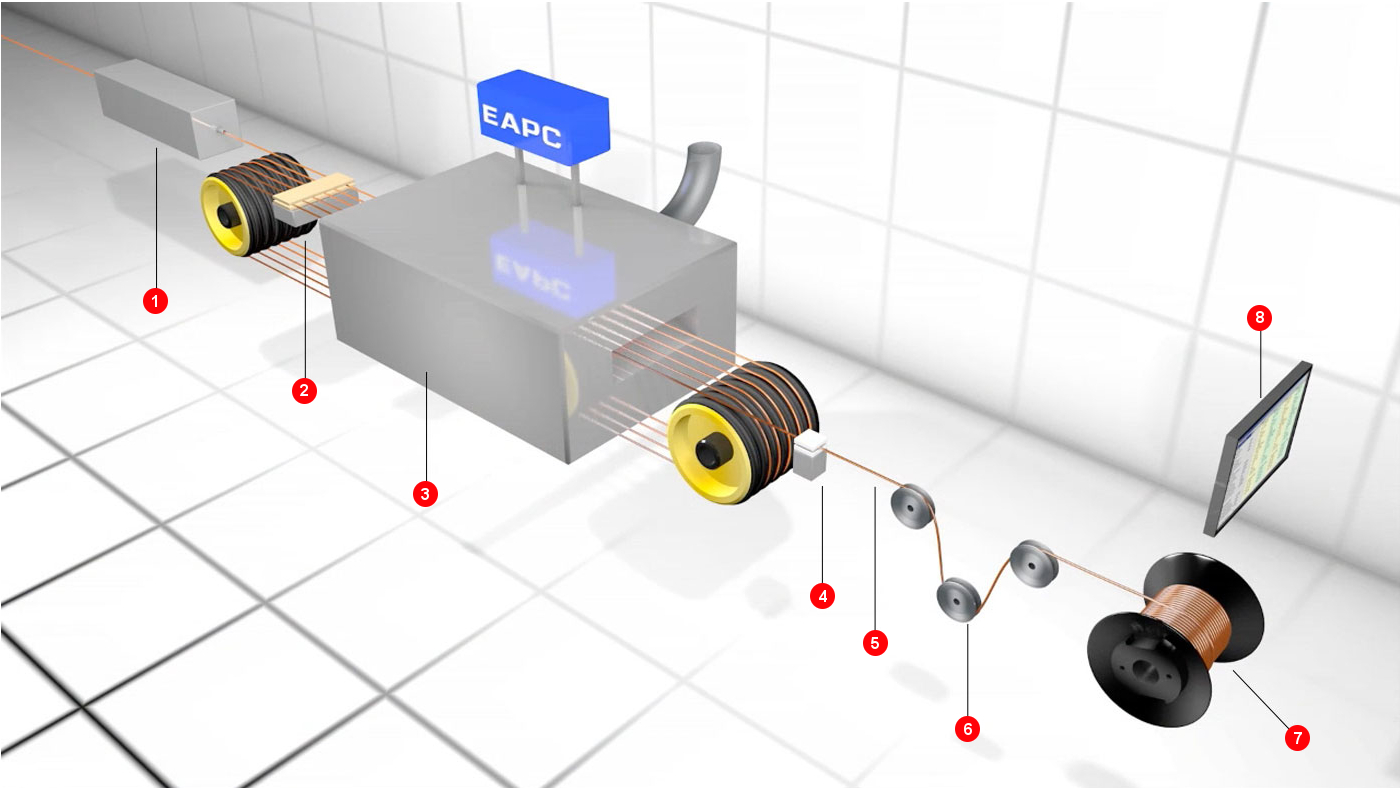

Proceso de Esmaltado

Todos los alambres están esmaltados en máquinas especiales de esmaltado desarrolladas y producidas por ELEKTRISOLA para nuestro uso exclusivo. El esmaltado es un proceso continuo, que consiste principalmente en el proceso de recristalizado, aplicación de esmalte, proceso de curado, aplicación de lubricante, control de tensión y embobinado.

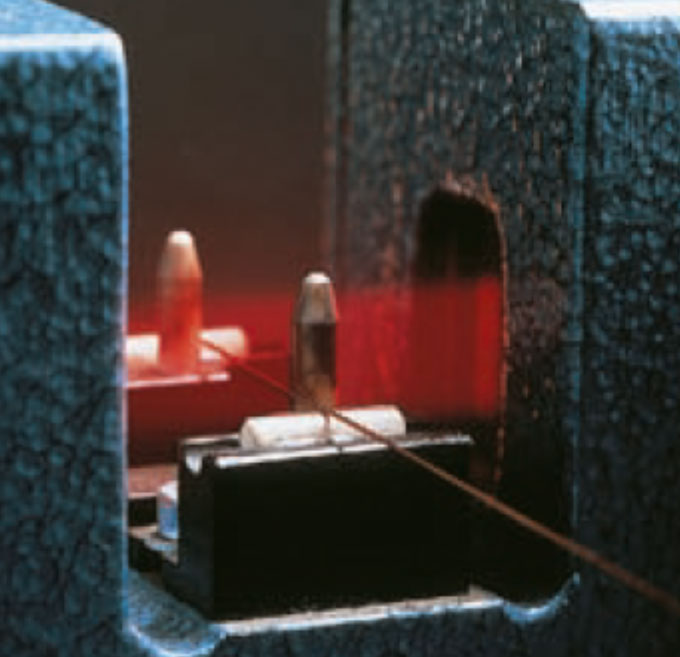

1. Proceso de Recristalizado

Durante el proceso de trefilado, la estructura de grano del alambre desnudo se ha modificado mediante deformación en frío. El recristalizado volverá a cristalizar el cobre y volverá a ablandarlo. Este proceso de alivio del estrés térmico se lleva a cabo bajo atmósfera protectora para evitar oxidar la superficie del alambre, lo que interferiría con la buena adherencia del revestimiento inicial de aislamiento más adelante en el proceso. La suavidad del alambre es un criterio importante para una buena capacidad de embobinado, en particular, reduce significativamente el número de roturas del alambre.

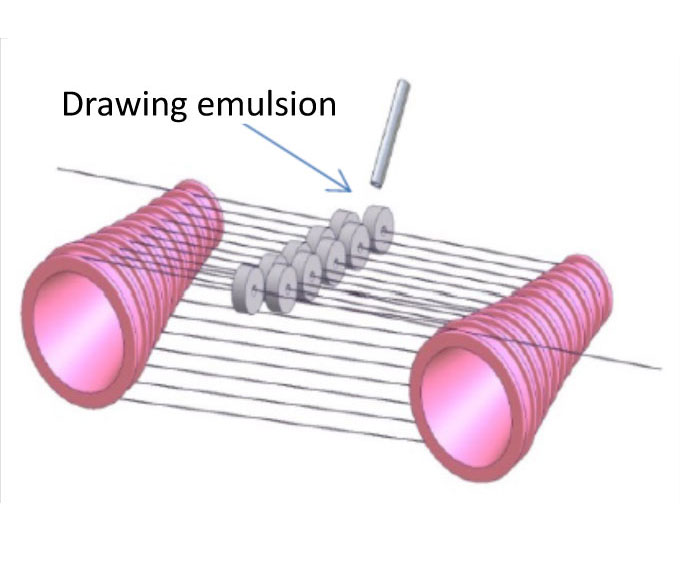

2. Aplicación de Esmalte

Hay 2 sistemas de aplicación principales para el esmaltado de alambres de embobinado, es decir, aplicación por medio de felpas y aplicación con dados. La aplicación con felpas se utiliza principalmente en la producción de alambre fino, mientras que la aplicación con dados se utiliza principalmente en la producción de alambre grueso. La capa de esmalte siempre debe aplicarse en tantas capas individuales como sea posible en lugar de menos capas y más gruesas para lograr mejores propiedades mecánicas y eléctricas.

3. Horno de Curado

Los disolventes contenidos en el esmalte líquido se expulsan en el horno de curado a alta temperatura y luego se queman catalíticamente utilizando la energía térmica de una manera respetuosa con el medio ambiente. El control de la temperatura es muy importante: si la temperatura es demasiado baja, se dejarán demasiados residuos de disolvente en la capa de esmalte, lo que provocará una mala adherencia y una reducción de las propiedades mecánicas y eléctricas. Si la temperatura es demasiado alta, la capa de esmalte será dura y quebradiza, lo que provocará grietas en la capa de aislamiento como resultado de la tensión mecánica.

4. Lubricación

Se aplica con precisión una cantidad definida de lubricante a la superficie de los alambres aislados. La lubricación es necesaria para lograr propiedades de embobinado consistentes y un embobinado del alambre sin fallas incluso a altas velocidades de embobinado.

5. Control del Diámetro

ELEKTRISOLA continuamente monitorea el Diámetro Exterior de todos los alambres después de la pasada final por el micrómetro de láser.

6. Control de la Tensión

Un control continuo de la tensión del alambre durante el proceso de esmaltado da como resultado un embobinado uniforme en el carrete. Con un control de tensión eficaz, se evita la elongación del alambre y, por tanto, un cambio de resistencia. Además, se pueden garantizar buenas propiedades de desembobinado a los clientes.

7. Embobinado

El acomodo del alambre y la velocidad de rotación del carrete son variables del proceso de embobinado que deben de controlarse muy de cercas. Esto da como resultado un rendimiento de desembobinado de alambre consistentemente bueno y minimiza otros problemas como alambres atrapados y enredados.

8. Monitoreo

La computadora informa al operador sobre todos los parámetros importantes del proceso.

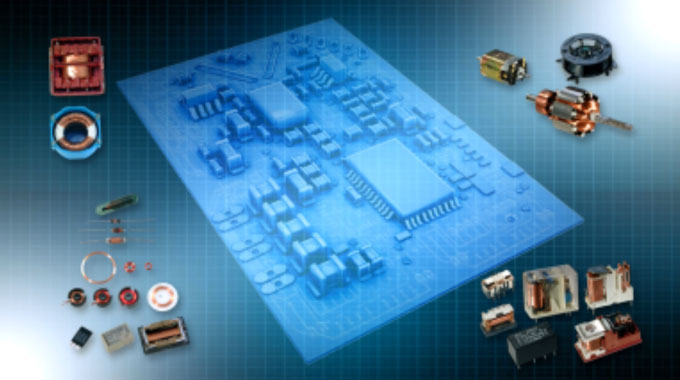

Automotriz

Electrodomésticos

Electrónica Industrial

Audio y Video

Computación

Relojes

Mars Rover

Alambre Esmaltado

Tipos de Alambre Esmaltado

Hay diferentes esmaltes disponibles en todo el mundo en Elektrisola. Además, hay algunos tipos disponibles en continentes seleccionados.

Datos Técnicos por Calibre

Los datos técnicos más importantes del alambre de cobre esmaltado están controlados por la resistencia y el diámetro exterior del alambre esmaltado. Estos y otros valores son importantes como soporte de ingeniería. Los diferentes estándares especifican estos valores de manera diferente, por lo tanto, los tres principales estándares mundiales se muestran por calibre. IEC (Comisión Eléctrica Internacional) es el estándar básico mundial armonizado. NEMA y JIS aún mantienen elementos adicionales de sus estándares más antiguos en su estándar nacional.

Alambre Autoadherible

Tipos de Alambre Autoadherible

Para nuestros alambres autoadheribles, existen tipos de esmaltes típicos disponibles para los diferentes mercados, dependiendo de los diferentes estándares y también de las diferentes aplicaciones principales para los mercados.

Datos Técnicos por Calibre

Los datos técnicos más importantes del alambre de cobre esmaltado están controlados por la resistencia y el diámetro exterior del alambre esmaltado. Estos y otros valores son importantes como soporte de ingeniería. Los diferentes estándares especifican estos valores de manera diferente, por lo tanto, los tres principales estándares mundiales se muestran por calibre. IEC (Comisión Eléctrica Internacional) es el estándar básico mundial armonizado. NEMA y JIS aún mantienen elementos adicionales de sus estándares más antiguos en su estándar nacional.

Materiales Conductores

Para la mayoría de las aplicaciones, el cobre se utiliza como material conductor, pero para aplicaciones especiales como bobinas de voz, actuadores u otras aplicaciones especiales, se necesitan metales de alto rendimiento.

ELEKTRISOLA tiene una amplia gama de materiales conductores especiales, como metal de bajo peso, alto rendimiento mecánico o de flexión. Además, se encuentran disponibles conductores recubiertos que muestran excelentes características para aplicaciones especiales.

Por favor contáctenos para metales que no se muestran en la tabla.